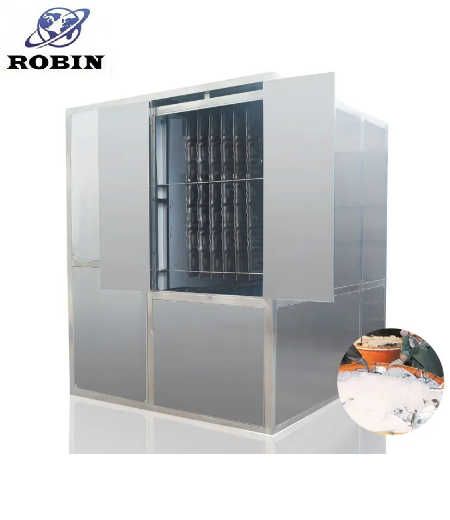

5 tons Commercial Plate Ice Machine for Fishing and Cooling

- Robin

- Shandong China

- 20 working days

- 100sets/Month

Robin plate ice maker masters two unique technologies: flat-plate heat exchange technology & circulating heat gas for ice dropping technology. The new-type ice making machine made via unique ice making technology and special ice dropping has solved the limitation of traditional ice making machine by frozen drum, and reaches the international leading level.

5 tons Commercial Plate Ice Machine for Fishing and Cooling

Products Features:

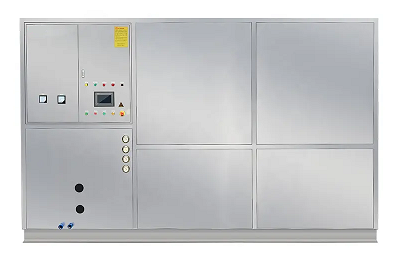

Techinical Parameter:

| Capacity | 5 Ton/24hours |

| Refrigerant | R22/R404A/R507/R449 |

| Compressor Brand | Copeland/Bitzer/Refcomp |

| Cooling Way | Water/Air Cooling |

| Compressor Power | 28 HP |

| Ice Cutter Motor | 1.5 KW |

| Power of Circulating Water Pump | 0.75 KW |

| Power of Water Cooling Pump | 2.2 KW |

| Cooling Tower Motor | 0.75 KW |

| Cooling Fan Motor | 2.7 KW |

| Machinery Unit Size(L*W*H) | 2250mm*2000mm*1950mm |

| Input Water Temp | 21degrees Celsius |

| Evaporating Temp | 25degrees Celsius |

| Condensing Temp | 40degrees Celsius |

| Supply power | 380V/50Hz(60Hz)/3P; 220V(230V)/50Hz/1P; 220V/60Hz/3P(1P); 415V/50Hz/3P; 440V/60Hz/3P. |

| The above data is subjected to the final design without notice. |

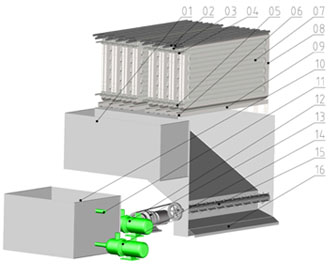

Ice Making Principle:

| When the refrigeration system begins operating normally, the water in the tank below is transported from the cold water tank to the cold water sprinkler by the cold water pump. It is then evenly sprinkled on the surface of the evaporator. Through the cycle working of the refrigerant, some water is created into plate ice, while the water which does not become ice returns to the cold water tank below and waits for the next water cycle. After a period of time the water cycle and refrigeration stops and the water and overheating refrigerants gas begin a heat exchange with the plate ice at the same time. The plate ice then loses adhesive force and the ice drops into the ice crushing gadget due to gravity. After the ice is off the water temperature becomes low and it returns into the water sink waiting the next cycle. |

Detailed Drawings of the Plate Ice Machine

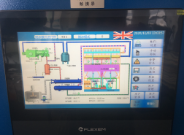

| Easy operation and stable performance Stable ice making capacity, PLC program control. As long as the ice capacity is selected, other procedures will be automatically finished under PLC program control without special care. |

Efficient ice doffing mode It’s unnecessary to introduce additional heat energy since the reversal hot Freon gas produces by plate ice machine itself is fed into the evaporator, thus it just take less than 120 seconds for the whole ice doffing process. |  |

| Meet the HACCP and FDA certification standard The machine is made of stainless steel 304, so it is anti-corrosive and has a very long lifespan. The plate ice is sanitary, clean and harmless to human. The machine can completely meet the requirements of the HACCP and FDA certification. |

Plate Ice Application:

Plate ice is usually used for ice storage systems and is also applied to concrete mixing plants, chemical plants, mines, fresh vegetables, fishing and aquatic insulations.