Direct Cooling Automatic Ice Block Machine

- Robin

- Shandong China

- 20 working days

- 100sets/Month

ROBIN production of ice machine includes flake ice machine series, tube ice machine series, cube ice machine series, block ice machine series, plate ice machine series and cold room, packing ice machine, ice crusher, cooling system. etc, complete set of refrigeration equipment, formed from pre-sales support, design, production, complete sets of installation and debugging, customer training, etc of a complete set of engineering and technical services. Products are mainly used in fresh supermarkets, hospitals, docks, chemical industry, concrete mixing, deep-sea fishing, aquatic products processing, Large-scale plant cooled industrial and commercial applications.

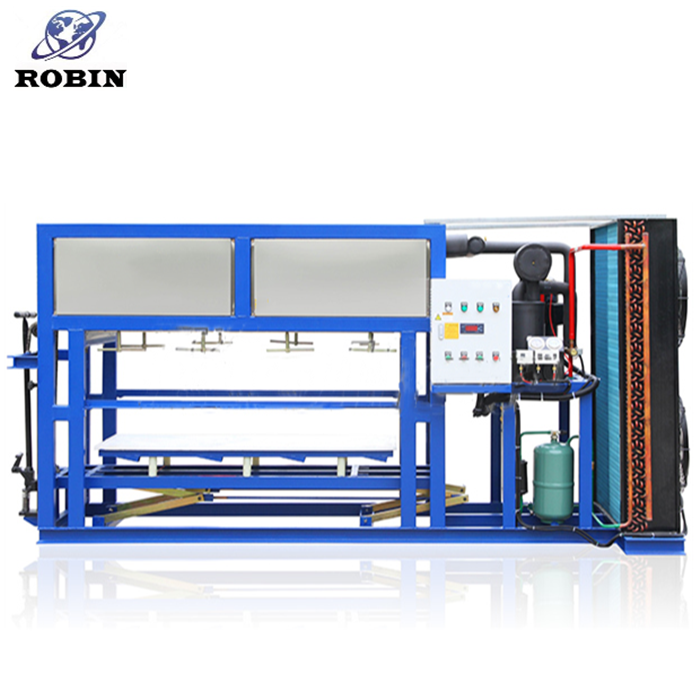

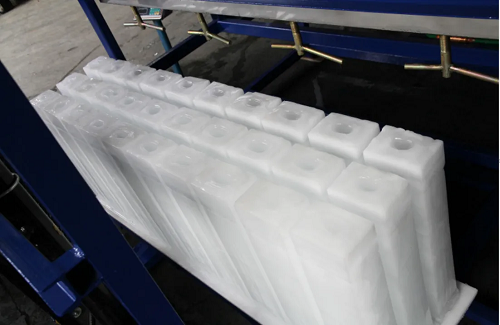

Direct Cooling Automatic Ice Block Machine

The advantage of the direct cooling block ice machine:

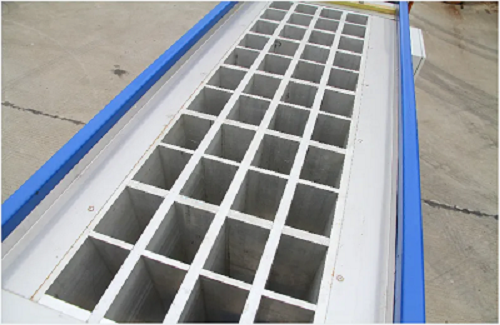

Characteristic of the direct-evaporation block ice machine is that its evaporator(ice mold or evaporatotion grid) is made of aluminum-magnesium alloy special light materials, and is specially designed and manufactured, and its thermal conductivity completely surpasses the traditional iron-made ice making barrels. The thermal conductivity of the alloy aluminum is 237W/MK, the thermal conducrivity of the galvanized iron plate is 80W/MK, and the thermal conductivity of the stainless steel is 17W/MK which is smaller, that is, the thermal conductivity of the aluminum alloy is 3 times than that of the iron. Thereforem the ice production speed of this product is much faster than the traditional ice making method. The ice making speed is faster, the energy consumption is lower, and the hygiene is cleaner(the level of anticorrosion is also greatly improved, teaching the food-greade standard). This is the main advantage of this type of product. A leap in the ice making industry has made our company unique in the ice making industry.

Technical Parameter:

| Capacity | 2 Ton/24hours |

| Refrigerant | R22/R404A/R507/R449 |

| Compressor Brand | Copeland/Refcomp/Bitzer |

| Cooling Way | Air Cooling |

| Ice Harvest Way | Manual Forklift |

| Compressor Power | 12 HP |

| Power of Lifting Device Motor | 0.75 KW |

| Machinery Unit Size(L*W*H) | 3800mm*900mm*1600mm |

| Machinery Unit Weight | About 1200kg |

| Input Water Temp | 21degrees Celsius |

| Evaporating Temp | 25degrees Celsius |

| Condensing Temp | 40degrees Celsius |

| Supply power | 380V/50Hz(60Hz)/3P; 220V(230V)/50Hz/1P; 220V/60Hz/3P(1P); 415V/50Hz/3P; 440V/60Hz/3P. |

| The above data is subjected to the final design without notice. |

Ice Size/pc | Ice Dimension (mm) (Thickness*Width*Height) | FreezingTime (Hours) | Ice Making Frequency (Times) |

5KG | 95*160*453 | 3 | 7 |

10KG | 95*260*500 | 3 | 7 |

15KG | 123*300*500 | 8 | 3 |

123*215*710 | 8 | 3 | |

20KG | 123*285*710 | 8 | 3 |

25KG | 123*350*710 | 8 | 3 |

155*280*710 | 8 | 3 | |

30KG | 155*315*710 | 8 | 3 |

50KG | 183*480*710 | 12 | 2 |

183*380*920 | 12 | 2 |

Block Ice Machine Details:

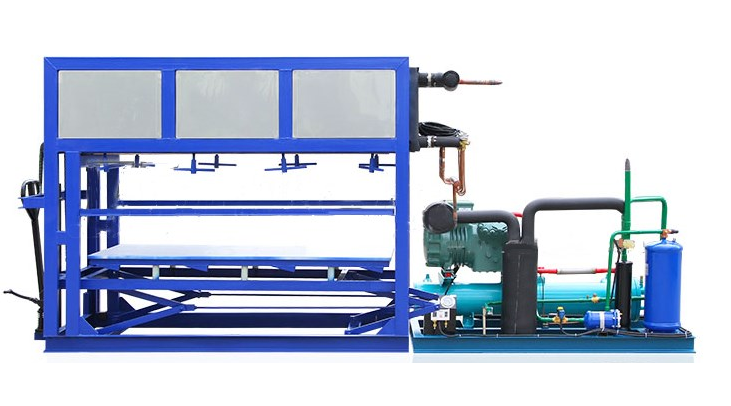

| Faster Ice Making and Lower Power Consumption Aluminum evaporator is of 3 times higher heat exchange efficiency than other steel [SUS304, galvanized steel], so ice block can be completely frozen faster. In this way, it can produce more ice blocks with lower power consumption. |

Clean ice Block and Eco-friendly Robin direct cooling ice block machine can make ice block directly without brine or any other material.Also it won't produce any pollution to the environment. |  |

| Longer service life Without salt or other material's corrosion, Robin direct cooling ice block machine can have longer service life and you need just clean the ice moulds regularly. The future maintenance investment is lower. Less Space Requirement For Robin direct cooling ice block machine is integrated design, it takes less space than the brine type ice block machine for the same capacity. |

Labor saving Equipped with Siemens PLC system, Robin direct cooling ice block machine only only your labor cost to add the water and take the ice blocks out, all other process is automatically finished. |  |

Block Ice Machine Application Fields

Ice factory at ports and docks;

Fresh preservation and cooling of aquatic products;foods during line haul;

Edible ice.