Fastest Ice Block Making Machine For Plant

- Robin

- Shandong China

- 30 to 45 working days

- 100 sets/Month

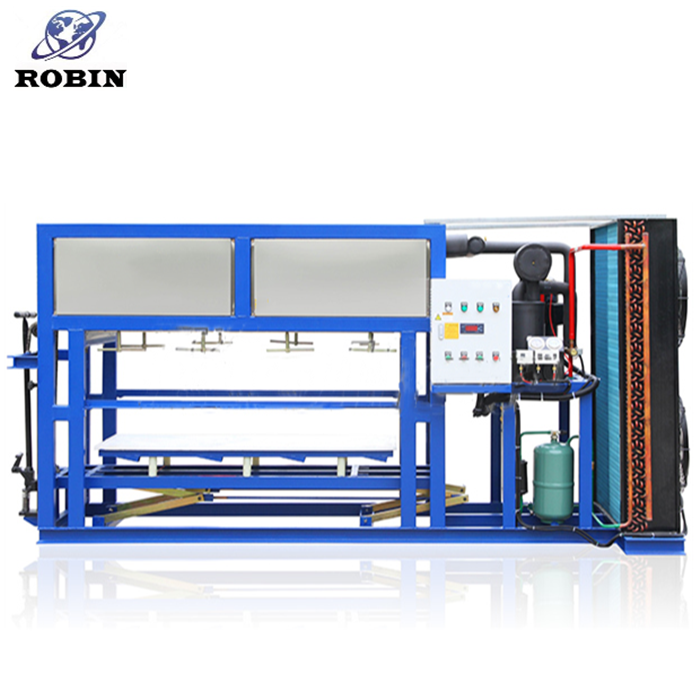

The direct cooling block ice machine is a block ice (ice brick) production equipment. The direct cooling ice machine evaporator adopts high-efficiency heat-conducting aluminum alloy material, which directly exchanges heat with the refrigerant, has low freezing temperature and fast ice making speed. Ice cubes melt slowly.

The direct cooling ice machine is highly automatic, automatic water supply, automatic ice making, automatic ice harvest, need no manual operation. The direct cooling ice machine does not need to use brine water. The ice mold does not need to be replaced after long time service. The equipment is safe and environmentally friendly, and the ice blocks are clean and hygienic, which can meet the food standard. Modular design, simple operation, small areaoccupation, easy installation, you can begin ice production as soon as connected to water and electricity.

Fastest Ice Block Making Machine For Plant

Main Features

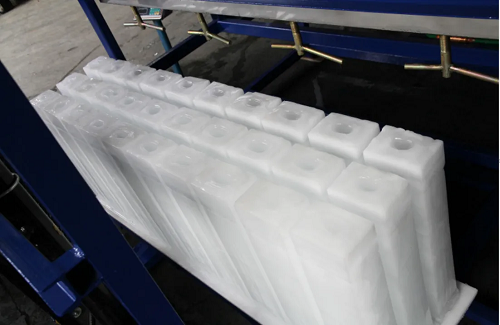

1). Sanitary and food grade block ice: Using aluminum plate evaporated directly, the ice can eat directly if the ice making water is clean enough;

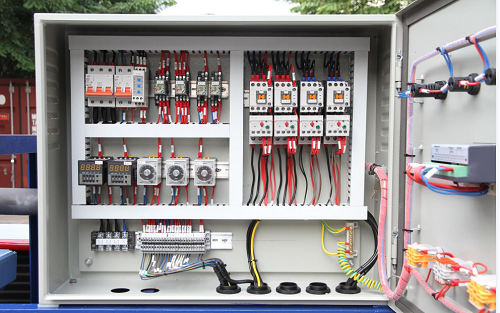

2). Automatic ice making and harvest under control of PLC micro computer system, easy operation;

3). Anti-rust and anti-corrosive material: the aluminum ice cans is a good material anti-rust and anti-corrosive, it means the lifespan will be longer;

4). All-in-One refrigeration system, less space is required, easier for installation;

5). Shorter freezing and harvesting cycle, save labor cost.

Technical Parameter

| Capacity | 2 Ton/24hours |

| Refrigerant | R22/R404A/R507/R449 |

| Compressor Brand | Copeland/Refcomp/Bitzer |

| Cooling Way | Air Cooling |

| Ice Harvest Way | Manual Forklift |

| Compressor Power | 12 HP |

| Power of Lifting Device Motor | 0.75 KW |

| Machinery Unit Size(L*W*H) | 3800mm*900mm*1600mm |

| Machinery Unit Weight | About 1200kg |

| Input Water Temp | 21degrees Celsius |

| Evaporating Temp | 25degrees Celsius |

| Condensing Temp | 40degrees Celsius |

| Supply power | 380V/50Hz(60Hz)/3P; 220V(230V)/50Hz/1P; 220V/60Hz/3P(1P); 415V/50Hz/3P; 440V/60Hz/3P. |

| The above data is subjected to the final design without notice. |

Ice Size/pc | Ice Dimension (mm) (Thickness*Width*Height) | FreezingTime (Hours) | Ice Making Frequency (Times) |

5KG | 95*160*453 | 3 | 7 |

10KG | 95*260*500 | 3 | 7 |

15KG | 123*300*500 | 8 | 3 |

123*215*710 | 8 | 3 | |

20KG | 123*285*710 | 8 | 3 |

25KG | 123*350*710 | 8 | 3 |

155*280*710 | 8 | 3 | |

30KG | 155*315*710 | 8 | 3 |

50KG | 183*480*710 | 12 | 2 |

183*380*920 | 12 | 2 |

Block Ice Machine Details:

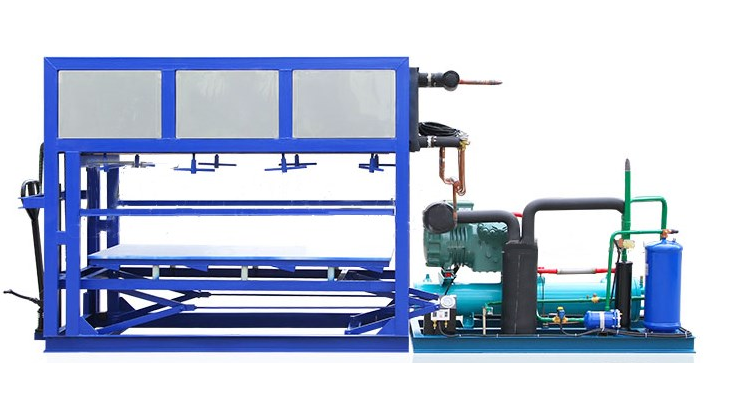

| Faster Ice Making and Lower Power Consumption Aluminum evaporator is of 3 times higher heat exchange efficiency than other steel [SUS304, galvanized steel], so ice block can be completely frozen faster. In this way, it can produce more ice blocks with lower power consumption. |

Clean ice Block and Eco-friendly Robin direct cooling ice block machine can make ice block directly without brine or any other material.Also it won't produce any pollution to the environment. |  |

| Longer service life Without salt or other material's corrosion, Robin direct cooling ice block machine can have longer service life and you need just clean the ice moulds regularly. The future maintenance investment is lower. Less Space Requirement For Robin direct cooling ice block machine is integrated design, it takes less space than the brine type ice block machine for the same capacity. |

Labor saving This PLC is just as the brain fora human being, it controls all the electrical parts of the machine, to guide all part when to work and stop, so the whole ice making and ice falling process are totally automatic. SIEMENS brand is also widely used over the world. |  |

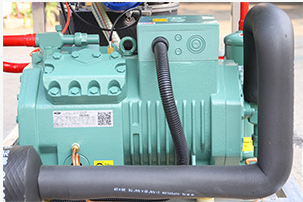

| Bitzer compressor The compressor is the only engine ofthe refrigeration system, it's just as the heart for a human being, so the quality of compressor enfiuence the refrigeration effect. Bitzer brand is good quality one, and widely used all over the world. |

Widely application of block ice

1).Fishery

2). Foods processing

3). Fresh keeping

4). Cooling

5). Ice sculpture