High Quality Industrial Ice Tube Making Machine

- Robin

- Shandong China

- 30 working days

- 100sets/Month

Tube ice machine application fields:

1.Edible ice factory.

2.Port ice plant.

3.Coffee shop,bar and hotel etc.

4.Supermarket,convenience shop and restaurant etc.

5.Aquatic products and food fresh preservation.

6.Logistic fresh preservation.

7.Chemical and concrete projects.

High Quality Industrial Ice Tube Making Machine

Why choose Robin to produce the machine

1.The pursuit of the perfect appearance -from rigorous attitude:

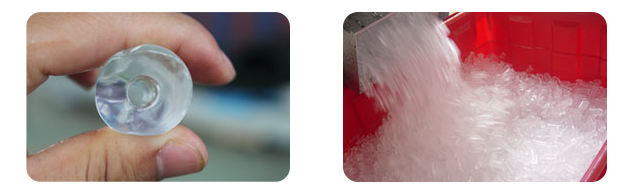

If you would like to enjoy the diamond grade edible tube ice, please choose the tube ice evaporator made of excellent material and best processing technology.

2.Best processing technology -from advanced processing equipment:

Pressure vessel: Pressure vessel with ASME authentication; professional security manufacturing processes;

3.Excellent material -from rigorous selection processes for decades:

Material: SUS304; Clean, sanitary, comply with food grade security standards;

4.Material Processing--CNC laser cutting machine;

5.Evaporator Processing--CNC electronic processing for the inner wall of the evaporator;

6.Equipment Insatllation--the most skilled technical workers, the most rigorous working attitude;

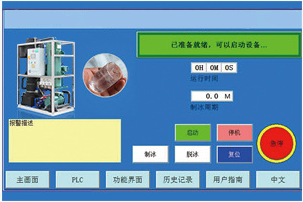

7.Intelligent control -from ROBIN full automatic electric box:

Material: Electrical components imported from international famous brands, such as Schneider, Siemens., etc.

Technical parameters of All the Robin Tube ice machine

Model | Daily output (T/ 24 h) | Compressor Power | Fan Power for Cooling Tower | Cooling Pump Power | Unit Size (L*W*H mm) (Integrated Type) | Unit N.W. (kg) | |

RBT-1T | 1 | 4.1 kw | 0.25 kw | 1.1 kw | 1100*900*1780 | 900 | |

RBT-2T | 2 | 7.44 kw | 0.25 kw | 1.5 kw | 1250*1000*1950 | 1200 | |

RBT-3T | 3 | 10 kw | 0.55 kw | 1.5 kw | 1300*1100*2200 | 1500 | |

RBT-5T | 5 | 19.9 kw` | 0.55 kw | 2.2 kw | 1600*1400*2250 | 1800 | |

Model |

Daily output |

Compressor | Fan Power for Cooling Tower |

Cooling Pump Power | Unit size (L*W*H mm) |

Unit N.W. (kg) | |

Main Host | Brine Tank | ||||||

RBT-10T | 10 | 27.9 kw | 1.5 kw | 4 kw | 1900*1600*1850 | 1200*1200*3390 | 3500 |

RBT-12T | 10 | 39.8 kw | 1.5 kw | 4 kw | 2400*1700*2000 | 1200*1200*3390 | 3700 |

RBT-15T | 15 | 46.4 kw | 1.5 kw | 5 kw | 2700*2000*2200 | 1500*1200*4250 | 4250 |

RBT-20T | 20 | 55.7 kw | 2.2 kw | 7.5 kw | 2800*2200*2500 | 1500*1200*4700 | 6500 |

RBT-30T | 30 | 83.6 kw | 2.2 kw | 7.5 kw | 3100*2200*2500 | 1800*1500*5700 | 7200 |

RBT -40T | 40 | 111.4 kw | 2.2 kw | 11 kw | 3900*2250*2500 | 2000*1500*6800 | 8300 |

RBT-50T | 50 | 139.3 kw | 3.75 kw | 15 kw | 4500*2250*2500 | 2200*1800*7200 | 9500 |

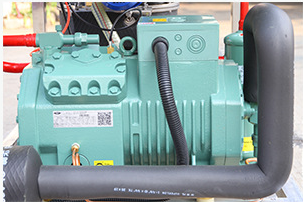

1. Compressor brand: Bitzer /Franscold ; Refrigerant: R 22/ R 404 A; Cooling Method: water cooling / air cooling.2.Power supply: | |||||||

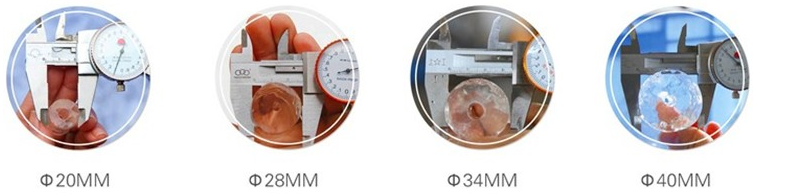

Ice tube Size as option

Tube ice outer diameter is 16mm,22mm, 28mm, 34mm, 40mm; The inner diameter can be adjusted according to the ice making time. Usually it's between 5~10mm.

| External Diameter | Standard Length | Freezing time |

| 16mm | 25mm | 14 minutes |

| 20mm | 30mm | 16 minutes |

| 28mm | 35mm | 18 minutes |

| 34mm | 45mm | 20 minutes |

| 40mm | 55mm | 25 minutes |

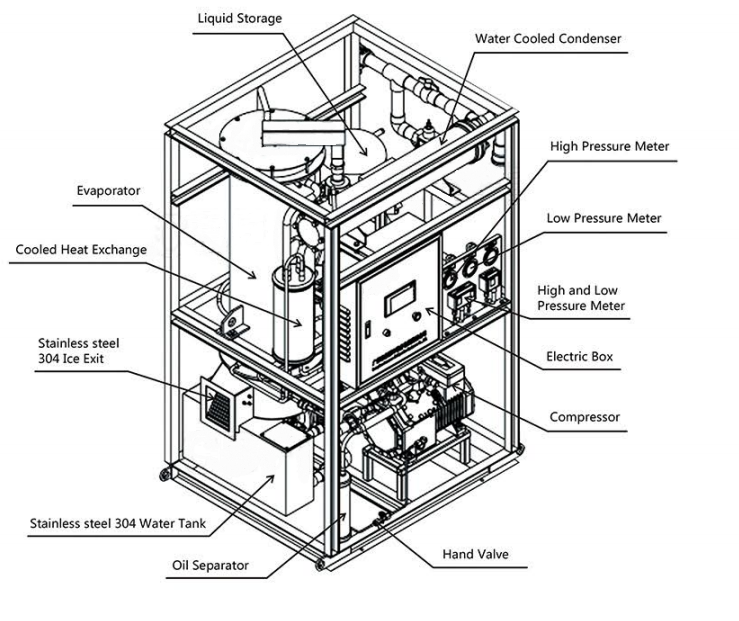

Detailed Drawings of the tube Ice Machine

| Bitzer compressor: high efficiency, low loss, low noise, long service life. |

| Touch screen: simple operation: the electric control box adopts PLC microcomputer program control, automatic ice forming, automatic ice dropping, automatic ice out and fault intelligent display. |  |

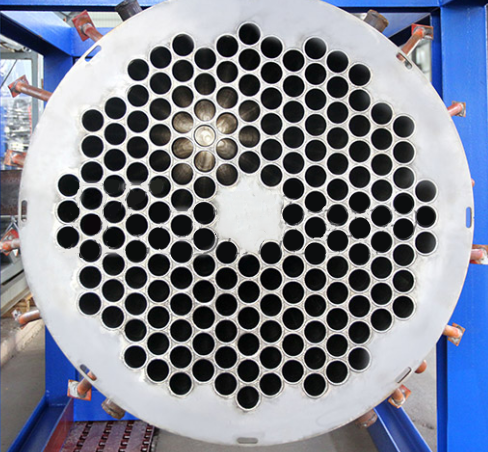

| Evaporation barrel: material using SUS304.PE, aluminum alloy and other materials processing, the use of large rounded corner over set.So that there is no dead Angle of cleaning inside the equipment. |

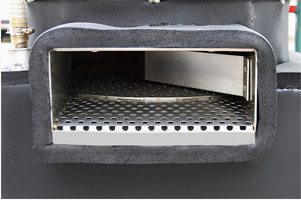

| Ice outlet: when the ice pipe falls, the ice cutting mechanism will operate and cut the ice pipe into the set size. |  |

| Evaporator: SS 304 inside, PU insulation and also the SS 304 cladding outside to keep the top quality and long life spans. |