Low Energy Consumption Tube Ice Maker For Seafood

- Robin

- Shandong China

- 30 working days

- 100sets/Month

Greatly shorten ice-doffing time, the whole process only takes 90 seconds. Compared with other ice making equipment,Robin tube ice machine has the advantages of compact structure, small area, low production cost, high cooling efficiency, and energy-saving.

Low Energy Consumption Tube Ice Maker For Seafood

Tube ice machine is a type ice machine, which produces cylinder shape ice with a hole in the middle; it adopts flooded evaporator model, which improves ice making efficiency and capacity. Meanwhile, compact structure design can save installation space.

Products Features:

1.Special ice making method to remove water impurity .The ice is hard and powderless.

2.The tube ice, in hollow tube shape,is transparent,sanitary and environment friendly.

3.Several dimensions for your option. Outer diameter:∅22,∅29,∅38,∅41mm and custom to your requirement.

4.Compared with flake ice,tube has longer melting time.

5.Suitable for stroing and transporting and applicable for several fields.

Technical parameters of All the Robin Tube ice machine

Model | Daily output (T/ 24 h) | Compressor Power | Fan Power for Cooling Tower | Cooling Pump Power | Unit Size (L*W*H mm) (Integrated Type) | Unit N.W. (kg) | |

RBT-1T | 1 | 4.1 kw | 0.25 kw | 1.1 kw | 1100*900*1780 | 900 | |

RBT-2T | 2 | 7.44 kw | 0.25 kw | 1.5 kw | 1250*1000*1950 | 1200 | |

RBT-3T | 3 | 10 kw | 0.55 kw | 1.5 kw | 1300*1100*2200 | 1500 | |

RBT-5T | 5 | 19.9 kw` | 0.55 kw | 2.2 kw | 1600*1400*2250 | 1800 | |

Model |

Daily output |

Compressor | Fan Power for Cooling Tower |

Cooling Pump Power | Unit size (L*W*H mm) |

Unit N.W. (kg) | |

Main Host | Brine Tank | ||||||

RBT-10T | 10 | 27.9 kw | 1.5 kw | 4 kw | 1900*1600*1850 | 1200*1200*3390 | 3500 |

RBT-12T | 10 | 39.8 kw | 1.5 kw | 4 kw | 2400*1700*2000 | 1200*1200*3390 | 3700 |

RBT-15T | 15 | 46.4 kw | 1.5 kw | 5 kw | 2700*2000*2200 | 1500*1200*4250 | 4250 |

RBT-20T | 20 | 55.7 kw | 2.2 kw | 7.5 kw | 2800*2200*2500 | 1500*1200*4700 | 6500 |

RBT-30T | 30 | 83.6 kw | 2.2 kw | 7.5 kw | 3100*2200*2500 | 1800*1500*5700 | 7200 |

RBT -40T | 40 | 111.4 kw | 2.2 kw | 11 kw | 3900*2250*2500 | 2000*1500*6800 | 8300 |

RBT-50T | 50 | 139.3 kw | 3.75 kw | 15 kw | 4500*2250*2500 | 2200*1800*7200 | 9500 |

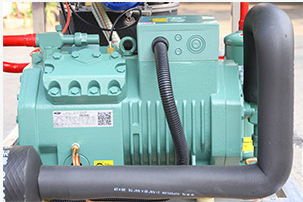

1. Compressor brand: Bitzer /Franscold ; Refrigerant: R 22/ R 404 A; Cooling Method: water cooling / air cooling.2.Power supply: | |||||||

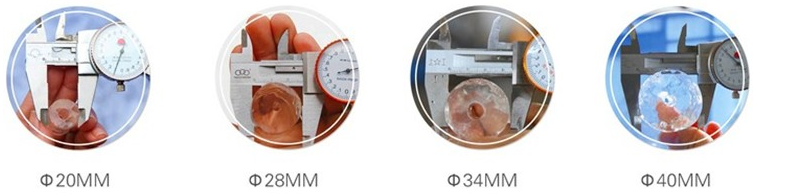

Ice tube Size as option

Tube ice outer diameter is 16mm,22mm, 28mm, 34mm, 40mm; The inner diameter can be adjusted according to the ice making time. Usually it's between 5~10mm.

| External Diameter | Standard Length | Freezing time |

| 16mm | 25mm | 14 minutes |

| 20mm | 30mm | 16 minutes |

| 28mm | 35mm | 18 minutes |

| 34mm | 45mm | 20 minutes |

| 40mm | 55mm | 25 minutes |

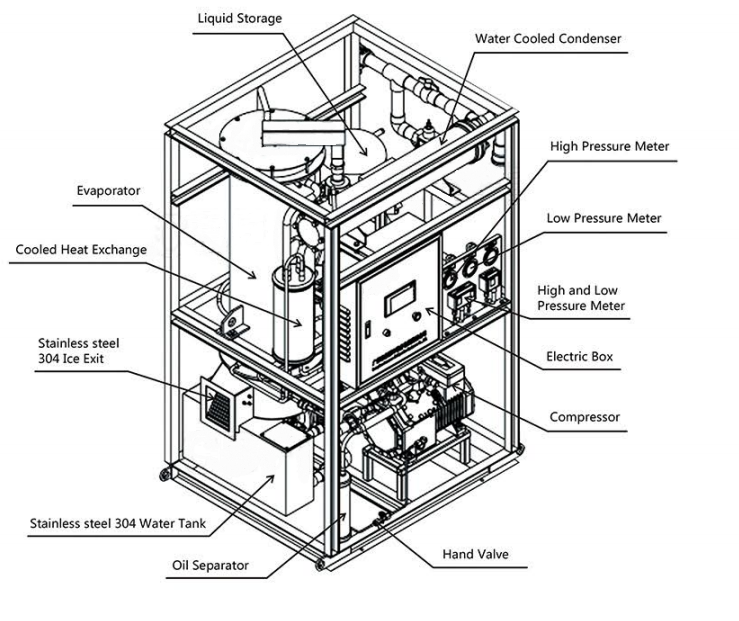

Detailed Drawings of the tube Ice Machine

| Bitzer compressor: The compressor is the only engine of the refrigeration system, it's just as the heart for a human being, so the quality of compressor enfluence the refrigeration effect. Bitzer brand is good quality one, and widely used all over the world. |

| Touch screen:which allows multiple functions such as automatic machine start and shut down; ice falling automatically when the freezing time is ensured, Automatic water making up. |  |

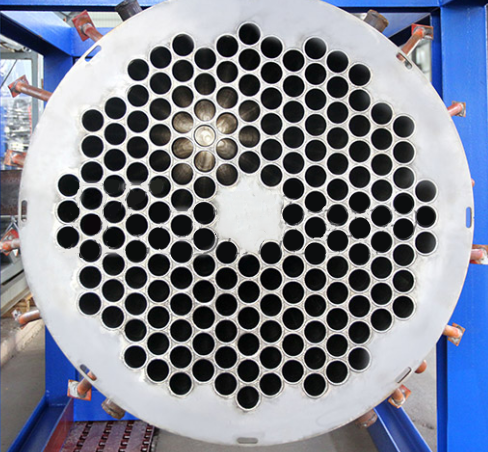

| Evaporation barrel: material using SUS304.PE, aluminum alloy and other materials processing, the use of large rounded corner over set.So that there is no dead Angle of cleaning inside the equipment. |

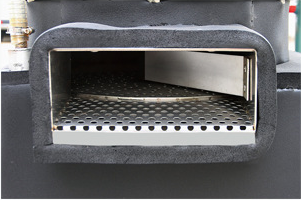

| Ice outlet: Ice discharging automatically, No need taking ice by hand which can guarantee the ice clean and sanitary, meanwhile, it is matched with ice packing system to package the ice by plastic bags. |  |

| Evaporator: SS 304 inside, PU insulation and also the SS 304 cladding outside to keep the top quality and long life spans. |