Comparison of advantages and disadvantages between water cooling and air cooling of industrial ice machine

Comparison of advantages and disadvantages between water cooling and air cooling of industrial ice machine

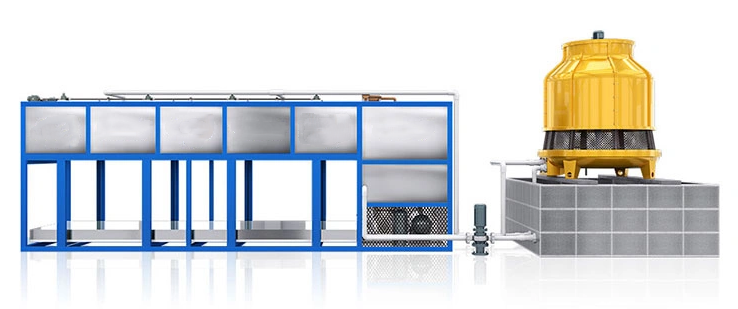

Ice making machine is a kind of mechanical equipment that generates ice after cooling water through evaporator by refrigerant of refrigeration system. According to the different condensing modes of the ice maker, the ice maker is divided into water cooler and air cooler. How to choose the ice machine condensation mode? Usually, small ice makers (daily production of 0.1-5 tons) choose more air cooling, large and medium-sized ice makers (daily production of 5-100 tons) choose more water cooling. The main difference between water-cooled and air-cooled ice makers is that water-cooled ice makers are cooled by water as a carrier.

I, The air-cooled condenser is a refrigerant through a long pipe (usually coiled into a solenoid), so that the heat is lost to the surrounding air. The thermal conductivity of copper pipe is strong, and it is often used for conveying steam. In order to improve the efficiency of the condenser, the heat sink with excellent heat conduction performance is often added to the pipeline, and the heat dissipation area is increased to accelerate the heat dissipation, and the air convection is accelerated through the fan to take the heat away.

II, The water-cooled condenser is imported from the pipe on the cylinder, and flows to the pipe outlet zigzagging through each baffle channel in sequence. The cooler medium uses double pipe flow, that is, the cooler medium enters half of the cooler pipe through the water distribution cover from the inlet, and then flows into the other half of the cooler pipe from the return water cover into the other side of the water distribution cover and the outlet pipe. In the process of double tube flow, the waste heat released by the heat absorbing medium is discharged from the water outlet to keep the rated working temperature of the working medium.

III, the difference between water cooling and air cooling and the comparison of advantages and disadvantages

1. Advantages of air cooling condenser: (1) No water resources, low operating cost; (2) Easy to install and use, without other supporting equipment, as long as the power can be put into operation; 3) No pollution to the environment; (4) Suitable for severe water shortage or scarce water supply areas.

2. Disadvantages of air cooling condenser: 1) High cost input; (2) The condensing temperature is higher, so that the operating efficiency of the refrigeration unit is reduced; (3) It is not applicable to areas with dirty air and dusty climate.

3. The advantages of water cooling condenser are as follows: (1) The condensing temperature of the refrigeration unit is low and the refrigeration efficiency is improved; (2) The initial input cost is lower than that of air cooling and evaporation cooling; (3) Good cooling effect, suitable for medium and large refrigeration systems.

4. Disadvantages of water cooling condenser: (1) It will consume water resources; (2) Water spraying has some influence on the surrounding environment; (3) Need to buy water tower, install water system, water supply system.

IV, Understand the limit condensing temperature of the refrigeration system. Choose ice machine condensation mode, first to understand the environment temperature. It is not higher than 55 ° C and not lower than 20 ° C. In general, it is not recommended to use water cooling condenser in areas where the ambient wet bulb temperature exceeds 42 ° C. Therefore, whether the water cooling condenser can be selected, the first thing to confirm the environmental wet bulb temperature. Generally, when designing water-cooled ice machines, the customer must provide the highest local annual ambient wet bulb temperature. At the same time, when the ambient temperature exceeds 50℃C, water cooling condenser can not be used, and the cooling tower is easy to be damaged by high temperature. Cooling towers must be used with shade protection.