1 Ton/day Commercial Tube Ice Machine

- Robin

- Shandong China

- 20 to 35 working days

- 100 sets/Month

1 ton tube ice machine

* All equipment except cooling tower is installed in steel frame.

* Meet the requirements of container transportation, easy to transport, move and install.

* Easy to use;The site can be put into operation only by providing water source and power source.

The standard power supply of the small tube ice machine is 380V/3P/50Hz. The power supply can be changed according to the actual situation, but it must be indicated when ordering.

1 Ton/day Commercial Tube Ice Machine

1 ton tube ice machine Introduction

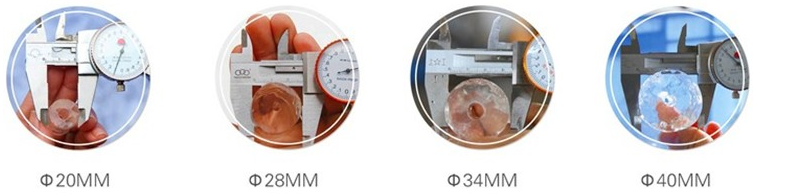

The ice tube looks like hollow cylinder.which has external diameter 20mm, 28mm, 34mm,40mm.Length ranging from 25-50mm, and the inner hole diameter can be adjusted according to ice-making time.

Daily capacity: 1ton/24hours.

Ice length: 30mm, 35mm, 40mm, 45mm, 50mm.

Ice diameter: 20mm, 28mm, 34mm, 40mm.

1 ton tube ice machine features

1. Harvest ice way: Hot gas defrosts

2. Ice tube Size: 20mm, 28mm, 34mm or 40mm in diameter; 30mm,35mm, 40mm, 45mm, 50mm in length; hollow and transparent ice.

3. Evaporator: seamless steel pipes

4. PLC program Logic Controller, which allows multiple functions such as automatic machine start and shut down; ice falling automatically when the freezing time is ensured, Automatic water making up.

5. Rotating Driver Ice Cutter: stainless steel 304 Ice Cutter Blade run by medium speed gear motor.

6. Install according to the operation manual and CD, Supply failure alarming system, and no requirement of skilled workers, high durability, and minimum maintenance.

7. Special ice outlet. Ice discharging automatically, No need taking ice by hand which can guarantee the ice clean and sanitary, meanwhile, it is matched with ice packing system to package the ice by plastic bags.

Technical Parameter of 1 ton Tube ice machine

Capacity | 1 Ton/24hours |

Refrigerant | R22/R404A/R507/R449 |

Compressor Brand | Copeland/Invotech/Danfoss |

Cooling Way | Water Cooling |

Compressor Power | 4 HP |

Ice Cutter Motor | 0.37 KW |

Power of Circulating Water Pump | 0.37 KW |

Power of Cooling Water Pump | 0.75 KW |

Cooling Tower Motor | 0.18 KW |

Machinery Unit Size(L*W*H) | 1500mm*1000mm*1750mm |

Machinery Unit Weight | About 900kg |

Input Water Temp | 21degrees Celsius |

Evaporating Temp | 25degrees Celsius |

Condensing Temp | 40degrees Celsius |

Supply power | 380V/50Hz(60Hz)/3P; 220V(230V)/50Hz/1P; 220V/60Hz/3P(1P); 415V/50Hz/3P; 440V/60Hz/3P. |

Ice tube Size as option

Tube ice outer diameter is 16mm,22mm, 28mm, 34mm, 40mm; The inner diameter can be adjusted according to the ice making time. Usually it's between 5~10mm.

| External Diameter | Standard Length | Freezing time |

| 16mm | 25mm | 14 minutes |

| 20mm | 30mm | 16 minutes |

| 28mm | 35mm | 18 minutes |

| 34mm | 45mm | 20 minutes |

| 40mm | 55mm | 25 minutes |

Detailed Drawings of the tube Ice Machine

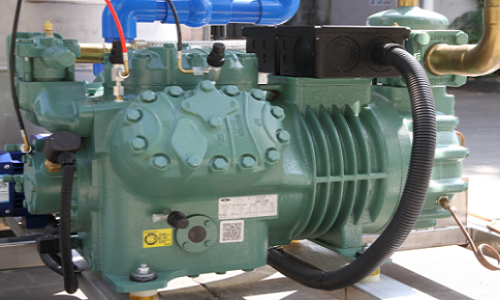

| German Bitzer compressor We use German Bitzer compressor. The product characteristics of BITZER compressors in Germany include high refrigeration capacities and energy efficiency ratios with economiser operation, as well as reliable continuous operation performance for a wide range of refrigerants. In addition, BITZER compressors enjoy an excellent brand image in the market High efficiency: high refrigeration capacity, energy efficiency ratio (COP value) 20 per cent higher than those of other compressor brands, with economiser operation. |

Touch Screen Controller The machine adopts the integrated design, compact structure, easy installation and use; PLC man-machine interface computer module, ice making and ice automatically switches off, save time and effort; All equipment using CAD, 3 d simulation assembly, arrangement of equipment parts and accessories, pipe to more reasonable, compact structure and not crowded, operation, maintenance more human; According to different working condition of customized, non-standard machines can be made. |

|

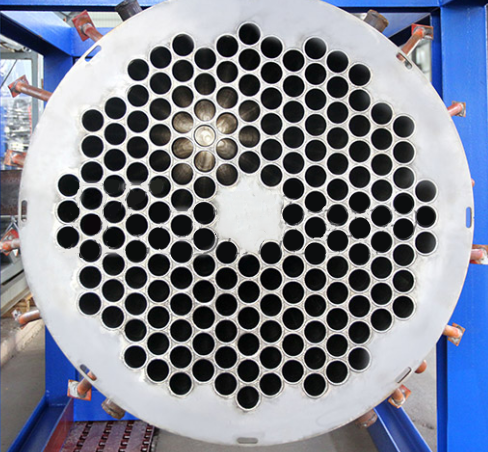

| Evaporator Evaporator is the kernel ofttube ice machine. Using 360° automatic welding machine, wield is compact and flat without gap, Refrigerant and water through the evaporator will not leak. The strong evaporator can increase the service time of machine. Seamless steel pipe, after annealing process, the material is tough and strong. Evaporator external insulation construction, anti-corrosion, more energy-saving, sufficient output |

High and low pressure controller This is one of the key technologies to ensure the safe and stable operation of the equipment, preventing damage to the compressor caused by abnormal pressure and safeguarding the entire refrigeration system. Ensures safe and efficient operation of the tube ice machine while protecting the operator and equipment from potential safety risks and damage.Use Denmark Danfoss for this pressure control to keep the pressure control preciously. |  |

Tube ice application

The tube ice produced by the tube ice machine is crystal clear and the length of the tube ice can be adjusted. The entire production process is clean and hygienic, without any harmful substances to the human body, and can be in direct contact with food. It is widely used in food preservation industries such as cold drinks, fisheries, and markets.

Packaging and Shipping

FAQ

1.What are the payment terms?

Our preferred method of payment is via wire transfer. The terms are as follows: an initial 40% deposit is required to secure your order, and the remaining 60% balance is to be settled prior to the delivery of your machine.

2.Do I need to install the ice machine myself?

For smaller models, the ice machines are shipped as a complete unit, requiring only the connection of utilities to operate. For larger units that are shipped in parts for easier transportation, we provide a comprehensive installation manual. The manual is straightforward, making the assembly process manageable. Should you encounter any difficulties, our technical support team is always available to assist you.

3.How long is the warranty on the ice machine?

We offer a comprehensive 18-month warranty from the date of purchase or delivery. During this period, we will supply any necessary spare parts free of charge if a failure occurs due to our manufacturing defect. Additionally, we provide lifetime technical support and advice to ensure your ice machine operates efficiently and reliably.

4. Are you add refrigerant in the ice machine?

The model which is for export will not added with refrigerant by default.If there are any special requirements,negotiations will be available

5. Do you test the ice machine in your factory?

Yes, Our ice machine be tested twice before shipping and we will send testing video to you.Factory inspection and operation test after installation at the buyer's destination.In addition, our company can provide a complete set of solutions for the actual needs of customers.Creating value and fulfilling customers is our principle.

6. Can I custom 220V 50HZ/ 380V 50HZ / 440V 60HZ three phase power ?

Yes we can custom power, voltage can suitable for your country, please make the power requirement be clear in your order.

7. Whats the deliver time of your machine?

standard power 220V 50HZ production 20-35 days;380V/440V custom power production time 30-35 days.

8. How Can You Guarantee The Quality?

We have our quality department to inspect the quality during the production process. We will test the whole machine in our workshop and testing pictures or videos can be provided to you for checking.