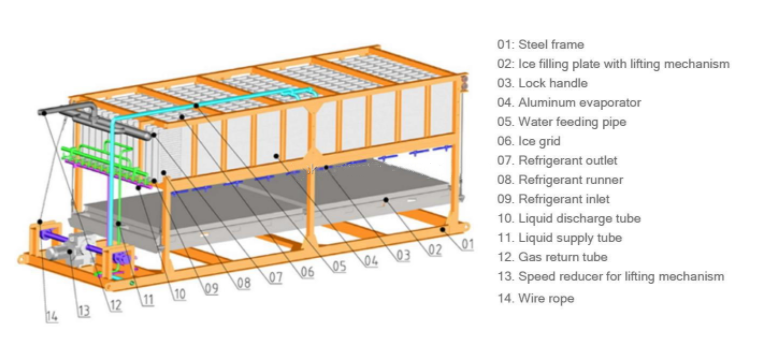

How Does Aluminum Direct Type Block Ice Machine Work?

As shown, Ice filling plate (02) will be elevated by wire rope (14) which is driven by speed reducer (13). Lift up the filling

plate to be fastened in the lock handle (03) and get the whole aluminum alloy plate evaporator (04) sealed. Add water into the icegrid (06) automatically through water feeding pipes (05). At the bottom of all ice grid there is a 5mm space ensures water can flow through each ice can. When water reaches to the standard level, it will stop to continue to add water automatically.

Refrigeration system starts to run after water adding process. Refrigerant flows into the refrigerant runner (08) of aluminum evaporator (04) from refrigerant inlet (09) and exchanges heat with water in ice grid to lower the water temperature.

In a certain time, all the water in ice can will turn into block ice. At this time, refrigeration system switches to ice defrost

mode. Hot gas enters into gas return tube (12) and becomes fluid in refrigerant runner (08), then back through liquid discharge tube (10) to the dry evaporator.

Hot gas defrosts ice surface and separates them from ice grid. At this time, refrigeration system stops to work. Speed reducer for lifting mechanism (13) drives wire rope to lower ice lifting plate to the bottom place of steel frame (01). The ice on filling plate can be manually moved away or the whole plate be taken away by forklift for swift and labor-free ice shift.