Robin flake ice machine application

There should be a lot of customers are not very clear about the ice machine for which industries, today to introduce to you the application of our Robin ice sheet machine.

1. Dairy production

In the fermentation process of yoghurt production, in order to control the fermentation time, temperature and humidity, and maintain the active biological factors of yoghurt, through the human-controlled temperature fermentation (artificially refrigerating the method to control the temperature below the normal fermentation temperature), in order to get the desired quality.

Adding a sufficient amount of clean and hygienic sheet ice is a good way to treat it.

2.Poultry processing

With the improvement of people's living standard, the requirement of food hygiene is more and more strict.

Especially for food export companies, there are strict requirements for each production link.

The national requirement of poultry slaughtering is to control the water temperature in the spiral precooling tank between 0°C and 4°C. If only the water cooler is used to cool the water temperature, the national requirement cannot be met.

Therefore, in the actual production process, a large number of sheets of ice must be added to the spiral precooling tank to control the water temperature.

3. Fruits and vegetables keep fresh

As the food safety of chemically synthesized preservatives is increasingly questioned, the storage and heat preservation of fruits, vegetables, meat and other foods are gradually turning to physical methods to focus on and maintain their natural quality, food safety, convenience and low energy consumption storage direction.

Physical preservation methods (such as natural cold source and wet cold storage) adapt to the trend of development and are gradually recognized and valued by people.

The wet cooling system is a method of ice storage by using the Robin sheet ice mechanism. This method obtains low temperature ice water and passes through the mixed heat exchanger to heat and mass transfer the ice water and the air in the reservoir, and obtains high humidity air close to the freezing point temperature to cool fruits and vegetables.

Fruits and vegetables can be quickly cooled to storage temperature and then kept at that temperature.

In combination with the synergistic effect of ozone, fruits and vegetables are protected from mold damage in low temperatures and high humidity.

4. Brewing industry

During the fermentation process of wine making, the temperature rises continuously due to biochemical reactions.

In order to control the fermentation temperature and time, maintain the biological activity of yeast and improve the stability of non-microorganisms, adding proper amount of clean ice sheet is an effective treatment method.

5.Bread and biscuit processing

During the process of making bread and biscuits, the temperature rise caused by friction will cause the flour to lose its activity and the gluten will also drop, which will affect the quality of bread and biscuits.

When whipping or reapplying cream, use ice sheets to cool down quickly to prevent fermentation.

Use proper amount of clean ice sheet to adjust the temperature to ensure product quality.

6.Processing of aquatic products

With the continuous improvement of people's living standard and the rapid development of export processing industry, the requirements for the internal quality of seafood are increasing day by day.

Ice is widely used in deep-sea fishing because of its physical properties, which both provide adequate moisture and cool temperatures.

Regardless of the development of mechanical refrigeration systems, they can only provide low temperatures, but not wet conditions.

The mechanical freezing system is easy to make the surface of aquatic products dry, dehydrated and even frostbite the surface of fish, resulting in the decline of seafood freshness.

Ice sheets provide the ideal cooling environment to keep the seafood in an ideal wet state, preventing spoilage and decay, as well as preventing dehydration and frostbite.

The melted ice water can also clean the surface of the seafood to remove bacteria and odors released by the seafood, achieving the ideal freshness preservation effect.

So a lot of ice is used in the fishing, storage, transportation and processing of Marine fisheries.

7. Meat processing

Pieces of ice has been widely used in the production of sausage and ham, in the process of stirring and mixing of the sausage, high-speed rotation of tumbling barrel and ingredients produced by friction between the high temperature not only promote the growth of bacteria, and changed the color and taste of meat, and can also lead to skim (fat), leading to the production of sausage bacteria, grey color, and taste hard and greasy.

When sliced ice is mixed into sausage ingredients, it cools quickly to the desired concentration, preserves the color and taste of the product, avoids degreasing and improves hygiene standards.

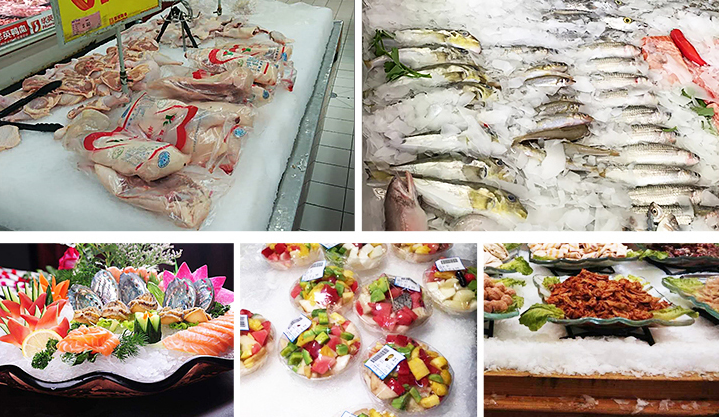

8. supermarket preservation

Ice is widely used in supermarkets to preserve and display fresh seafood and meat.

Because the surface of the sheet ice is dry and smooth, it does not scratch the surface of the fish, thus maintaining the air permeability of the underlying seafood, ensuring the original flavor of the product, and preventing the loss of product due to dehydration and hypoxia.

9.Biopharmaceutical and laboratory refrigeration

In order to control the reaction temperature and maintain bioactivity in the process of biopharmaceutical and laboratory refrigeration, it is necessary to add sheet ice to control the temperature and ensure the quality of drugs and experimental products.

10.Marine fishing

Seawater ice sheet machine uses stainless steel, corrosion resistant aluminum alloy, surface special treatment alloy, Freon refrigerant integration and the formation of durable design, parts loss is small, suitable for long-term continuous operation.

A special roller is used to make ice anywhere, no matter what the sea water is.

Using seawater to make ice directly on fisheries can reduce the load on ships and significantly save fuel costs compared to loading heavy ice from ports.

Our new model makes the swing Angle within 35 degrees, can maintain the water circulation without overflow, and can be used normally.

The ice wafer takes up little space and is quiet, and can be installed in the cabin. You can choose the type you want according to the amount of ice you use.