The working principle of tube ice machine

The working principle of tube ice machine

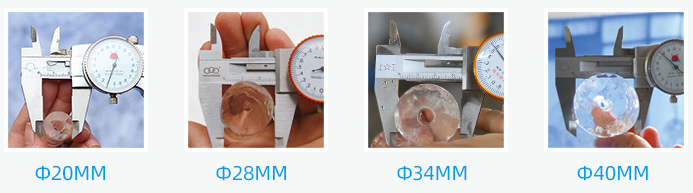

Tube ice is a regular hollow cylinder with an outer diameter of 20 mm, 28 mm, 34 mm, and 40 mm and a height of 25~42 mm to 42 mm. The diameter of the inner hole in the middle of the pipe ice machine can be adjusted according to the ice making time, generally between 5 mm and 10 mm.

Features: ice thick, transparent, beautiful, long storage, not easy to melt, good air permeability.

Application: daily consumption, vegetable preservation, fishing boat aquatic products preservation, etc.

Features of tube ice machine:

Ice quality: water through the tube ice machine filter, ice crystal clear, ice quality meet the standard.

Design: The tube ice machine adopts simulation assembly, the layout of the parts and accessories of the pipe ice machine equipment and the direction of the pipeline is more reasonable, the structure is compact and not crowded, and the operation and maintenance is more humane.

Safety and hygiene: All the evaporator materials of the tube ice machine are made of PE, aluminum alloy and other materials, with over-designed large rounded corners, and the inside of the tube ice machine equipment is clean without dead corners.

Properties: Using special alloy material and unique heat treatment process, the evaporator has better thermal conductivity.

Water saving and energy saving: each tube ice machine compression condensing unit is equipped with liquid return pipe, liquid supply pipe, evaporation temperature, condensation temperature control, return air overheating, oil return control and other heat exchangers, so that the compressor unit in a safe condition of stable operation, so as to obtain a higher C.O.P value.

Customized: The tube ice machine can operate normally under the working conditions of ambient temperature -20~+50℃ and inlet water temperature +0.5~+45℃. Not only can we provide you with a variety of standard refrigeration equipment, but also can be customized according to the actual needs of special conditions of the refrigeration system. At the same time, we can also according to your different power supply conditions for non-standard design.

Stable and reliable: The design of the tube ice machine reduces the unnecessary transmission parts inside the equipment, making the pipe ice machine equipment more simple and reliable. The unit is generally equipped with low water level, water flow, full ice, compressor high pressure, compressor low pressure, compressor oil pressure and other protection. Make the pipe ice machine equipment stable, reliable, safe operation, continuous operation of more than 30,000 hours without failure.

Automatic: THE ice making process is automatically controlled by PLC computer module, which is clear at a glance.

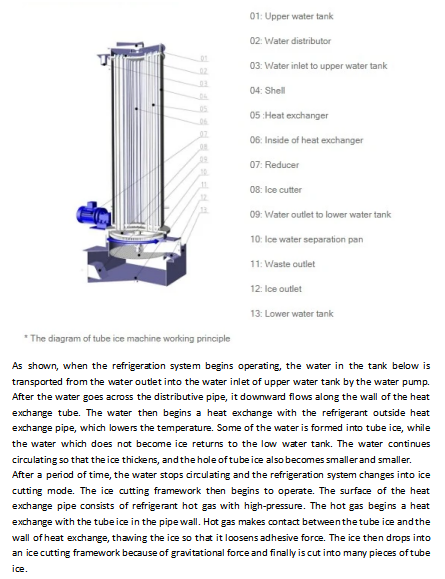

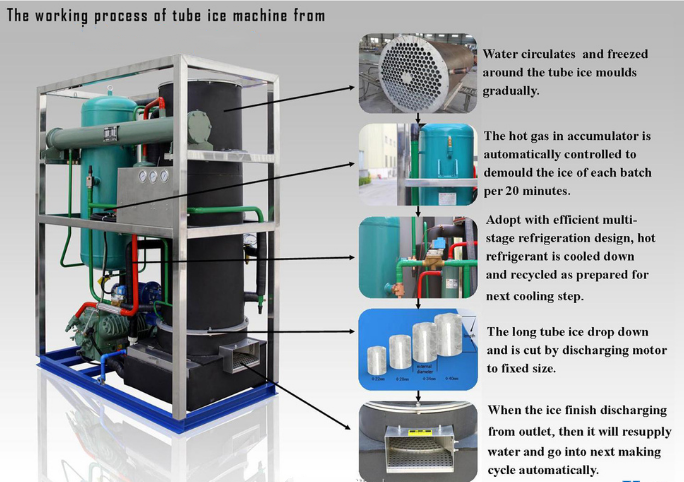

After the normal operation of the tube ice cooling system, the water in the lower water tank is transported from the outlet to the inlet of the upper water tank by the cold water pump. Water flows downward along the inner wall of the heat exchange tube in a spiral flow through the water divider, and carries out heat exchange with the refrigerant outside the heat exchange tube, resulting in a temperature reduction. Some of the water forms a tubular Popsicle inside the heat exchange tube, and the unfrozen water flows back into the lower tank. As the water circulates, the ice thickens, and the holes in the tubes get smaller and smaller.

After a certain time, stop the water cycle, become de-icing mode shell ice machine, ice cut operation, external surface of the heat exchange tube into a high pressure refrigerant heat, heat and heat exchange tube wall of the shell ice, shell ice melting and heat exchange tube wall contact part of the shell ice loss of adhesion, due to gravity, cut into the ice is cut into a shell ice.