5 T Tube Ice Making Machine With Bitzer Compressor

- Robin

- Shandong China

- 30 working days

- 50sets/Month

5 ton tube ice machine Mainly used for human consumption such as freeze drinks, mix wines, coolfoodstuffs. And also used for chemical cooling, food processing, fisheries, poultry-processing, meat plants etc.

We take advanced technics in production to meet your request about tube ice.

Cutter Motors: Built with heavy duty design to give years of reliable ice-sizing service.

Freezer: Of high quality stainless steel for all water and ice contact surfaces providing corrosion resistance.

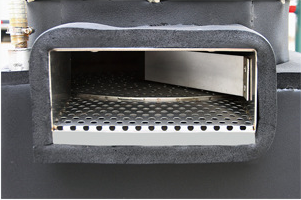

Cutter: Stainless steel cutters driven by gear motors are uniquely designed to produce both cylindrical and crushed ice simply by reversing the motor of the cutter using a switch on the control panel that controls this function.

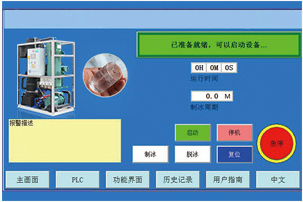

Control Panel: Gives use access to the automatic electrical system which performs sequences for freezing and thawing precisely and dependably then makes great convenience to the customer to operate the machine and settle the trouble.

5 ton air cooled Tube Ice Making Machine With Bitzer Compressor

5 ton tube ice machine is a very good choice for a start of your ice business. Working with a water filter and a packing machine, a 3 ton tube ice plant is all completed. We provide you with tube ice plant solution design, helping you with the position design, water pipe arrangement and etc.

Products Features:

* 3D designed to ensure the container transportation. Easy for installation & maintaining

* All materials have contact with ice we use food grade SUS304 stainless steel to ensure the safety of our ice.

*PLC intelligent controlled, full automatic production, need no human operation.

*Automatic laser welding to make the welding work nice and no leak, ensured the low fault rate.

*Special water system design to make ice good and evenly thickness, clear and pure

*Able to match the stainless steel conveyor and ice bin, and hand or automatic package system.

Technical parameters of All the Robin Tube ice machine

Model | Daily output (T/ 24 h) | Compressor Power | Fan Power for Cooling Tower | Cooling Pump Power | Unit Size (L*W*H mm) (Integrated Type) | Unit N.W. (kg) | |

RBT-1T | 1 | 4.1 kw | 0.25 kw | 1.1 kw | 1100*900*1780 | 900 | |

RBT-2T | 2 | 7.44 kw | 0.25 kw | 1.5 kw | 1250*1000*1950 | 1200 | |

RBT-3T | 3 | 10 kw | 0.55 kw | 1.5 kw | 1300*1100*2200 | 1500 | |

RBT-5T | 5 | 19.9 kw` | 0.55 kw | 2.2 kw | 1600*1400*2250 | 1800 | |

Model |

Daily output |

Compressor | Fan Power for Cooling Tower |

Cooling Pump Power | Unit size (L*W*H mm) |

Unit N.W. (kg) | |

Main Host | Brine Tank | ||||||

RBT-10T | 10 | 27.9 kw | 1.5 kw | 4 kw | 1900*1600*1850 | 1200*1200*3390 | 3500 |

RBT-12T | 10 | 39.8 kw | 1.5 kw | 4 kw | 2400*1700*2000 | 1200*1200*3390 | 3700 |

RBT-15T | 15 | 46.4 kw | 1.5 kw | 5 kw | 2700*2000*2200 | 1500*1200*4250 | 4250 |

RBT-20T | 20 | 55.7 kw | 2.2 kw | 7.5 kw | 2800*2200*2500 | 1500*1200*4700 | 6500 |

RBT-30T | 30 | 83.6 kw | 2.2 kw | 7.5 kw | 3100*2200*2500 | 1800*1500*5700 | 7200 |

RBT -40T | 40 | 111.4 kw | 2.2 kw | 11 kw | 3900*2250*2500 | 2000*1500*6800 | 8300 |

RBT-50T | 50 | 139.3 kw | 3.75 kw | 15 kw | 4500*2250*2500 | 2200*1800*7200 | 9500 |

1. Compressor brand: Bitzer /Franscold ; Refrigerant: R 22/ R 404 A; Cooling Method: water cooling / air cooling.2.Power supply: | |||||||

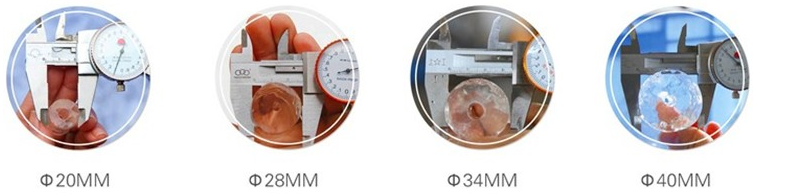

Ice tube Size as option

Tube ice outer diameter is 16mm,22mm, 28mm, 34mm, 40mm; The inner diameter can be adjusted according to the ice making time. Usually it's between 5~10mm.

| External Diameter | Standard Length | Freezing time |

| 16mm | 25mm | 14 minutes |

| 20mm | 30mm | 16 minutes |

| 28mm | 35mm | 18 minutes |

| 34mm | 45mm | 20 minutes |

| 40mm | 55mm | 25 minutes |

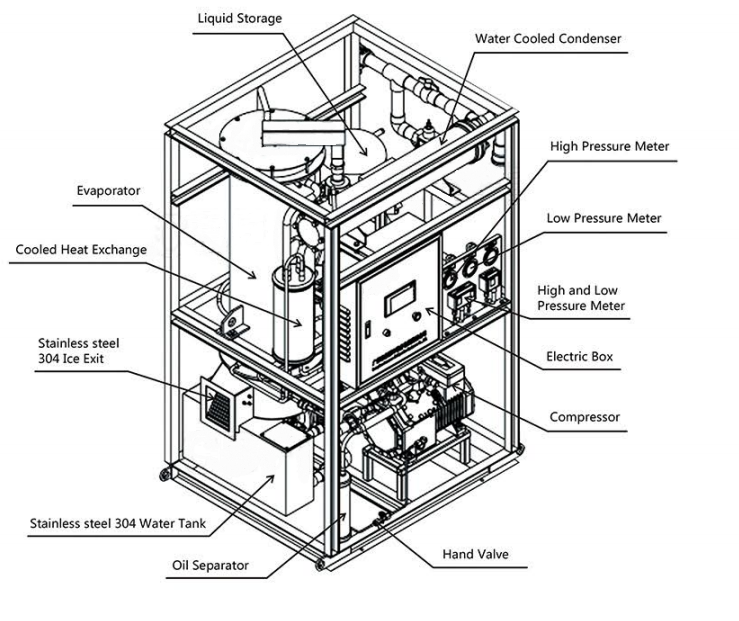

Detailed Drawings of the tube Ice Machine

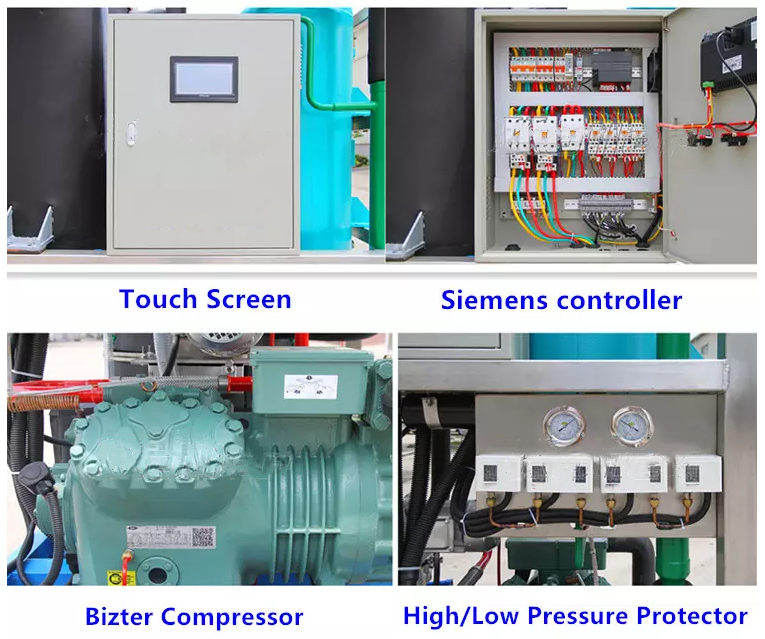

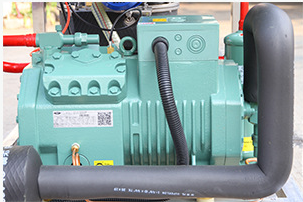

| Bitzer compressor: high efficiency, low loss, low noise, long service life. |

| Touch screen: simple operation: the electric control box adopts PLC microcomputer program control, automatic ice forming, automatic ice dropping, automatic ice out and fault intelligent display. |  |

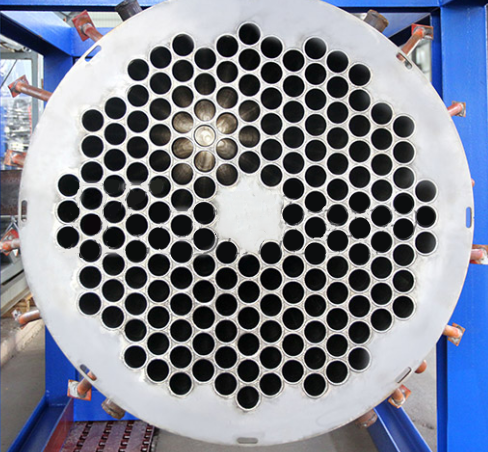

| Evaporation barrel: material using SUS304.PE, aluminum alloy and other materials processing, the use of large rounded corner over set.So that there is no dead Angle of cleaning inside the equipment. |

| Ice outlet: when the ice pipe falls, the ice cutting mechanism will operate and cut the ice pipe into the set size. |  |

| Evaporator: SS 304 inside, PU insulation and also the SS 304 cladding outside to keep the top quality and long life spans. |