Competitive 10 T/24 Hrs Crystal edible Tube Ice making Machine for hotel bars

- Robin

- Shandong China

- 45 working days

- 20sets/Month

10 ton tube ice machine

Robin 10 ton tube ice machine is a type ice machine, which produces cylinder shape ice with a hole in the middle; it adopts flooded evaporator model, which improves ice making efficiency and capacity. Meanwhile, compact structure design can save installation space. Ice thickness and hollow part size can be adjusted according to customer requirements. Under PLC program control system to work automatically, the machine has high capacity, low-power consumption, and minimal maintenance.

10 Ton Crystal edible Tube Ice making Machine

10 ton Tube ice machine is one kind of ice machine. Because of the irregular length and hollow tube, so we called it tube ice. Our tube ice is hollow,cylindrical ice with external diameter of φ22mm,φ28mm,or φ35mm and length of 25-50mm.The diameter of the inner tube ice hole is usually φ5-10mm,but can be adjusted according to the ice making time. The thickness of the tube ice is thick and transparent, the storage period is long, it is not easy to melt.

Robin Tube ice machine features:

(1)The tube ice machine adopts the integrated design, compact structure, easy installation and use;

(2)PLC man-machine interface computer module, ice making and ice automatically switches off, save time and effort;

(3)All equipment using CAD, 3D simulation assembly, arrangement of equipment parts and accessories, pipe to more

reasonable,compact structure and not crowded, operation, maintenance more human;

(4)According to different working condition of customized, non-standard tube ice machines can be made.

Tube Ice machine working process:

1. Ice making process

As shown, when refrigeration system start to operate normally, low temperature refrigerant liquid enters into shell through refrigerant inlet, and it exchanges heat with water inside heat exchange pipe . After heat is absorbed and evaporated, it runs back to compressor through refrigerant outlet. Water in the tank is pump out of water outlet and delivered up to the inlet of tank. After water goes across the distributive pipe , it downwardly flows along the wall of heat exchange tubes and forms water film. The water then begin to exchange heat with the refrigerant outside the heat exchange tubes . When temperature lowers down, water freezes and ice formed inside heat exchange tubes

2. Ice doffing process

As ice reaches a certain thickness, water route system stops circulation. Reduction gear begins to run, and outside heat exchange tubes is replaced by hot refrigerant gas which then melts the surface of ice. The ice harvests from heat exchange pipe because of gravitational force and falls into ice cutter . Ice column finally is cut into 30-50mm length pieces of tube ice. Tube ice drops down and threw to ice outlet .

Technical parameters of All the Robin Tube ice machine

| Model | RBT-2T | RBT-3T | RBT-5T | RBT10T |

| Ice output | 2t/24h | 3t/24h | 5t/24h | 10t/24h |

| Ice tube diameter(mm) | φ29 | φ29 | φ29 | φ29 |

| Cooling Capacity(kW) | 17.9 | 27.4 | 48.8 | 80.2 |

| Evaporating temperature(ºC) | -15 | -15 | -15 | -15 |

| Condensing temperature(ºC) | 40 | 40 | 40 | 40 |

| Input power(kW) | 8.55 | 14.69 | 23.8 | 43.75 |

| Compressor input power(kW) | 6.7 | 11.9 | 18.6 | 33.8 |

| Ice cut reducer input power(kW) | 0.37 | 0.37 | 0.75 | 0.75 |

| Water pump input(kW) | 0.55 | 0.55 | 1.5 | 2.2 |

| Condenser Fan input power(kW) | 0.75 | 1.5 | 2.2 | 5.5 |

| Water pump of cooling tower(kW) | 0.18 | 0.37 | 0.75 | 1.5 |

| Power Specifications | 3P/380V/50Hz or 220V-480V 60hz | |||

| Water Pressure | 0.1Mpa-0.5Mpa | |||

| Refrigerant | R22, R404A, R507A, R449A | |||

| Standard ambient temp.(ºC) | 30 | |||

| Standard Water Temp.(ºC) | 20 | |||

| Water Consumption(M3/h) | 0.084 | 0.126 | 0.21 | 0.42 |

| Water supply tube Diameter | 1-1/4" | 1-1/4" | 2" | 2" |

| Overflow pipe | 1" | 1" | 1-1/4" | 1-1/4" |

| Drain pipe | 1" | 1" | 1-1/4" | 1-1/4" |

| Ice machine Weight(kg) | 1150 | 1280 | 1600 | 2750 |

| Ice Machine Diameter(mm) | 1650*1300*2150 | 1650*1300*2150 | 1750*1400*2250 | 2300*1600*3100 |

| Dimension of cooling tower(mm) | φ920*1830 | φ1165*1645 | φ1385*2150 | φ1880*2120 |

| Weight of cooling tower(kg) | 190 | 200 | 500 | 975 |

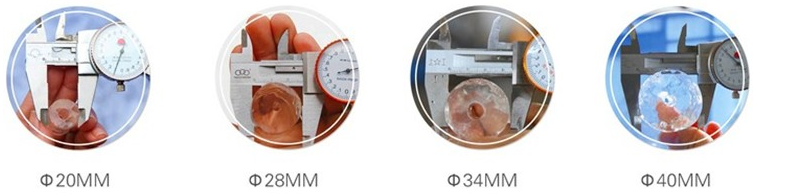

Ice tube Size as option

Tube ice outer diameter is 16mm,22mm, 28mm, 34mm, 40mm; The inner diameter can be adjusted according to the ice making time. Usually it's between 5~10mm.

| External Diameter | Standard Length | Freezing time |

| 16mm | 25mm | 14 minutes |

| 20mm | 30mm | 16 minutes |

| 28mm | 35mm | 18 minutes |

| 34mm | 45mm | 20 minutes |

| 40mm | 55mm | 25 minutes |

Detailed of the 10 ton tube Ice Machine

| CompressorThe compressor is the only engine of the refrigeration system, it's just as the heart for a human being, so the quality of compressor enfluence the refrigeration effect. Bitzer brand is good quality one, and widely used all over the world. Internationally renowned brands, long service life, good stability, high refrigeration efficiency, and low maintenance cost in the later stage. It adopts double parallel connection, good maintenance, small starting power, and smoother operation of the equipment. |

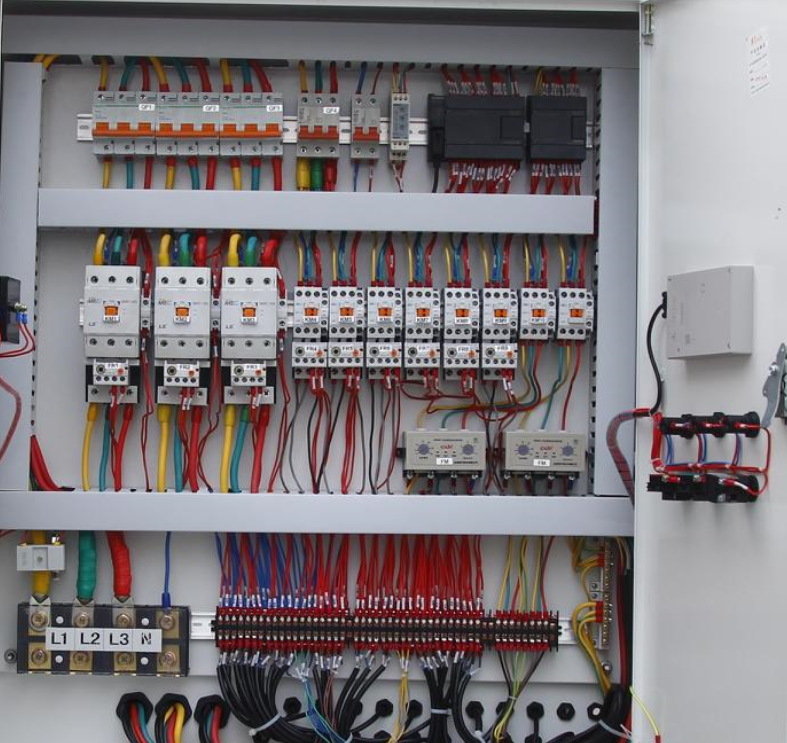

Siemenz PLC and Touch screen Ice discharge automatically hygienic and labor-saving Like the brain of the human being to control the machine do the proper work in the right time. The ice thickness can be adjusted. Record the history of machine work Set the operating parameters of the machine Easy to find fault causes in the event of a machine failure |

|

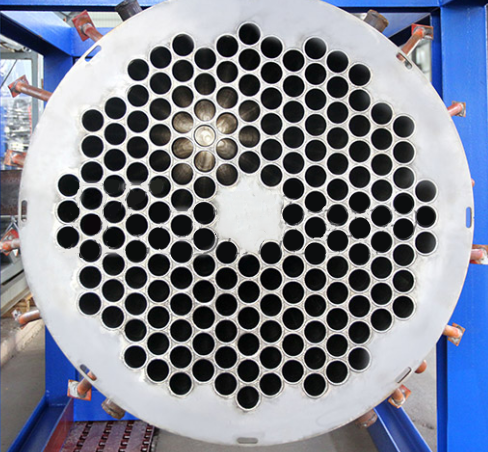

| Tube ice machine-Evaporator (1)The tube ice maker evaporator using high quality stainless steel 304 and other materials processing, meet international health standards; (2)we can do the OEM and follow you requirements for the trade mark . If you need ,we can produce evaporative condenser according to your design or conditions .The customized packing for tube ice machine condenser is also at your service. |

High and low voltage protection This is one of the key technologies to ensure the safe and stable operation of the equipment, preventing damage to the compressor caused by abnormal pressure and safeguarding the entire refrigeration system. Ensures safe and efficient operation of the tube ice machine while protecting the operator and equipment from potential safety risks and damage. |  |

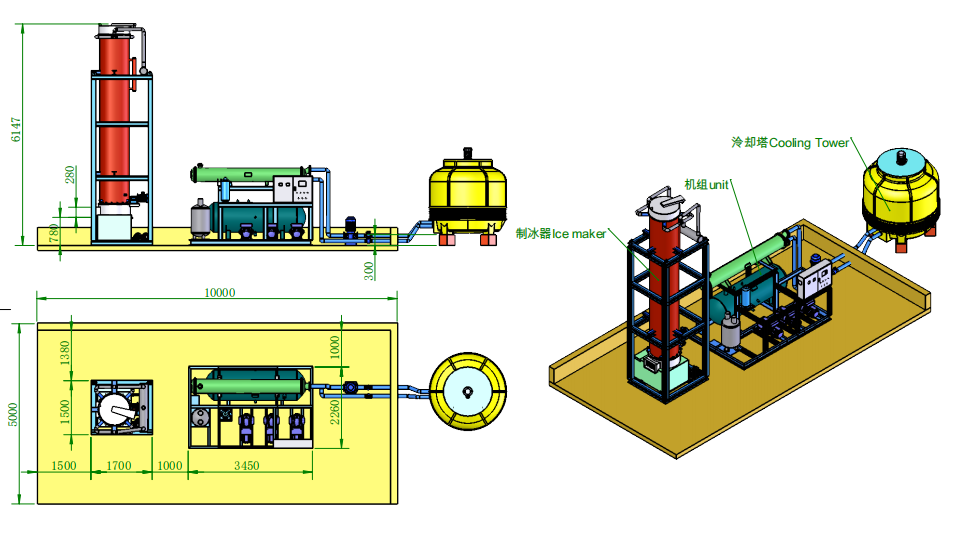

| Tube ice machine-Cooling tower All small type water-cooled tube ice machines are designed as integral type. Water in the cooling tower is delivered by pump into condenser. The temperature goes high after it exchanges heat with refrigerant. Then the high temperature water is delivered back to the top of cooling tower for cooling. The cooled water recycled to the sunk below and be used again. In the process of heat dissipation, some water will be evaporated into the air. Hence, cooling tower needs constant water supply when ice machine is running. |

3D Drawing of the Tube ice machine

10 ton Tube ice Application

Tube ice, especially the hollow column ice produced by tube ice machine, has a wide range of applications in many fields because of its regular shape, high hardness and slow melting.

Food processing and preservation: In the food processing industry, the fresh ice provided by tube ice machine can be used for preservation of seafood and meat, which can extend the shelf life of food by lowering the temperature. In addition, beverage production lines require large quantities of ice for cooling to ensure the taste and quality of beverages. The hollow design of tube ice increases the specific surface area of the ice, which helps to reduce the temperature of the food quickly. At the same time, due to its slow melting speed, it can maintain a low-temperature environment for a long time, which makes it ideal for use in the long-time preservation and transportation of food.

Cold chain logistics: in cold chain logistics, tube ice machine can provide a stable ice source for food products that need to be kept at low temperatures during transportation to ensure the freshness and quality of food products during transportation. Tube ice has a slow melting speed and high hardness, which is very suitable for cold storage and freshness preservation in long-distance transportation.

Catering industry: the catering industry has the same huge demand for ice, tube ice machine can quickly provide high-quality ice, used to make drinks, refrigerated ingredients, etc., to enhance the customer's dining experience. In addition, tube ice can also be used to make ice sculptures, chilled desserts, etc., to increase the ornamental and fun of the dining place.

Supermarkets and superstores: Supermarkets and superstores usually need to use a large amount of ice in the area of fish, meat and fresh products to keep these products at a low temperature and prevent deterioration. The high throughput of tube ice machines meets this need and ensures that fresh products in supermarkets and hypermarkets are always kept in the best condition.

After-sales service

1. During the production process of the machine, we will confirm the production progress of the machine with you in real time, and provide debugging quality inspection videos and reports at any time.

2. Arrange one-to-one technical engineers to serve you and provide professional service advice.

3. 18 months long-term warranty (other companies usually 12 months)

4. During the warranty period, if there is any problem with the machine, we will unconditionally provide raw material parts for free. If necessary, we can arrange technicians to visit your home for maintenance and repair.

5. After the warranty period, if any problem occurs on the machine, we will also arrange engineers to provide professional service + original spare parts (spare parts cost at your own expense)