Competitive 10 T/24 Hrs Crystal edible Tube Ice making Machine for hotel bars

- Robin

- Shandong China

- 45 working days

- 20sets/Month

10 ton tube ice machine

Robin 10 ton tube ice machine is a type ice machine, which produces cylinder shape ice with a hole in the middle; it adopts flooded evaporator model, which improves ice making efficiency and capacity. Meanwhile, compact structure design can save installation space. Ice thickness and hollow part size can be adjusted according to customer requirements. Under PLC program control system to work automatically, the machine has high capacity, low-power consumption, and minimal maintenance.

10 Ton Crystal edible Tube Ice making Machine

10 ton Tube ice machine is one kind of ice machine. Because of the irregular length and hollow tube, so we called it tube ice. Our tube ice is hollow,cylindrical ice with external diameter of φ22mm,φ28mm,or φ35mm and length of 25-50mm.The diameter of the inner tube ice hole is usually φ5-10mm,but can be adjusted according to the ice making time. The thickness of the tube ice is thick and transparent, the storage period is long, it is not easy to melt.

Robin Tube ice machine features:

(1)The tube ice machine adopts the integrated design, compact structure, easy installation and use;

(2)PLC man-machine interface computer module, ice making and ice automatically switches off, save time and effort;

(3)All equipment using CAD, 3D simulation assembly, arrangement of equipment parts and accessories, pipe to more

reasonable,compact structure and not crowded, operation, maintenance more human;

(4)According to different working condition of customized, non-standard tube ice machines can be made.

Tube Ice machine working process:

1. Ice making process

As shown, when refrigeration system start to operate normally, low temperature refrigerant liquid enters into shell (04) through refrigerant inlet, and it exchanges heat with water inside heat exchange pipe (06). After heat is absorbed and evaporated, it runs back to compressor through refrigerant outlet. Water in the tank (13) is pump out of water outlet (09) and delivered up to the inlet (03) of tank (01). After water goes across the distributive pipe (02), it downwardly flows along the wall of heat exchange tubes (06) and forms water film. The water then begin to exchange heat with the refrigerant outside the heat exchange tubes (05). When temperature lowers down, water freezes and ice formed inside heat exchange tubes

2. Ice doffing process

As ice reaches a certain thickness, water route system stops circulation. Reduction gear (07) begins to run, and outside heat exchange tubes (05) is replaced by hot refrigerant gas which then melts the surface of ice. The ice harvests from heat exchange pipe (05) because of gravitational force and falls into ice cutter (08). Ice column finally is cut into 30-50mm length pieces of tube ice. Tube ice drops down and threw to ice outlet (12).

Technical parameters of All the Robin Tube ice machine

| Model | RBT-2T | RBT-3T | RBT-5T | RBT10T |

| Ice output | 2t/24h | 3t/24h | 5t/24h | 10t/24h |

| Ice tube diameter(mm) | φ29 | φ29 | φ29 | φ29 |

| Cooling Capacity(kW) | 17.9 | 27.4 | 48.8 | 80.2 |

| Evaporating temperature(ºC) | -15 | -15 | -15 | -15 |

| Condensing temperature(ºC) | 40 | 40 | 40 | 40 |

| Input power(kW) | 8.55 | 14.69 | 23.8 | 43.75 |

| Compressor input power(kW) | 6.7 | 11.9 | 18.6 | 33.8 |

| Ice cut reducer input power(kW) | 0.37 | 0.37 | 0.75 | 0.75 |

| Water pump input(kW) | 0.55 | 0.55 | 1.5 | 2.2 |

| Condenser Fan input power(kW) | 0.75 | 1.5 | 2.2 | 5.5 |

| Water pump of cooling tower(kW) | 0.18 | 0.37 | 0.75 | 1.5 |

| Power Specifications | 3P/380V/50Hz or 220V-480V 60hz | |||

| Water Pressure | 0.1Mpa-0.5Mpa | |||

| Refrigerant | R22, R404A, R507A, R449A | |||

| Standard ambient temp.(ºC) | 30 | |||

| Standard Water Temp.(ºC) | 20 | |||

| Water Consumption(M3/h) | 0.084 | 0.126 | 0.21 | 0.42 |

| Water supply tube Diameter | 1-1/4" | 1-1/4" | 2" | 2" |

| Overflow pipe | 1" | 1" | 1-1/4" | 1-1/4" |

| Drain pipe | 1" | 1" | 1-1/4" | 1-1/4" |

| Ice machine Weight(kg) | 1150 | 1280 | 1600 | 2750 |

| Ice Machine Diameter(mm) | 1650*1300*2150 | 1650*1300*2150 | 1750*1400*2250 | 2300*1600*3100 |

| Dimension of cooling tower(mm) | φ920*1830 | φ1165*1645 | φ1385*2150 | φ1880*2120 |

| Weight of cooling tower(kg) | 190 | 200 | 500 | 975 |

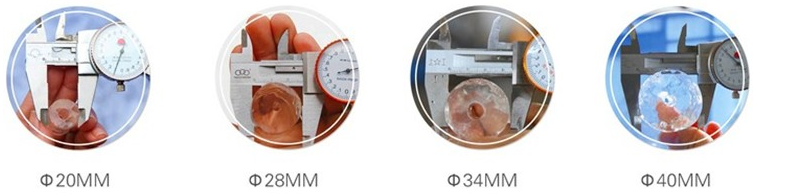

Ice tube Size as option

Tube ice outer diameter is 16mm,22mm, 28mm, 34mm, 40mm; The inner diameter can be adjusted according to the ice making time. Usually it's between 5~10mm.

| External Diameter | Standard Length | Freezing time |

| 16mm | 25mm | 14 minutes |

| 20mm | 30mm | 16 minutes |

| 28mm | 35mm | 18 minutes |

| 34mm | 45mm | 20 minutes |

| 40mm | 55mm | 25 minutes |

Detailed of the 10 ton tube Ice Machine

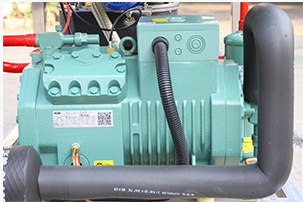

| Compressor Name: Bitzer |

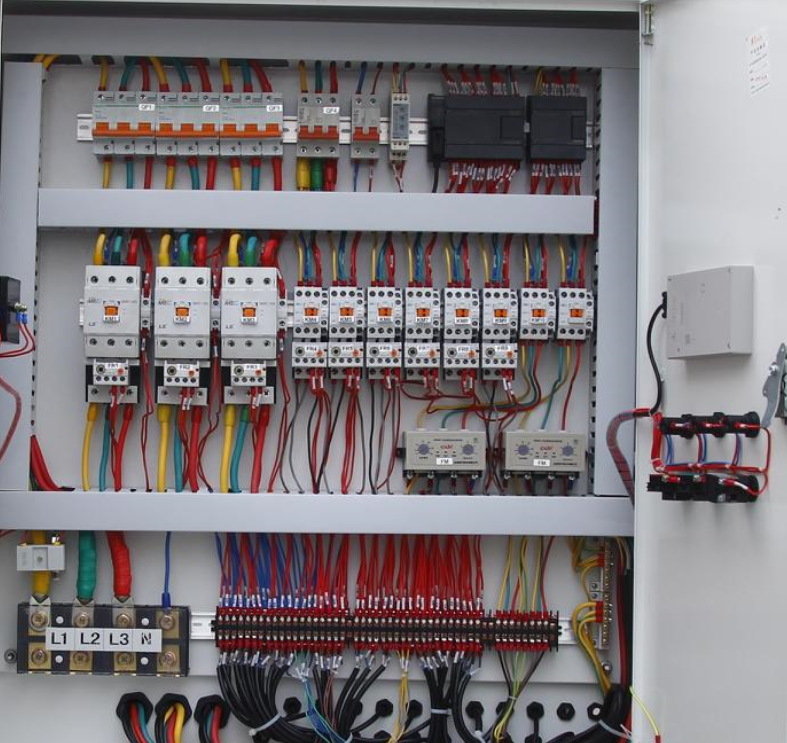

Siemenz PLC and Touch screen: Touch screen: simple operation: the electric control box adopts PLC microcomputer program control, automatic ice forming, automatic ice dropping, automatic ice out and fault intelligent display. |  |

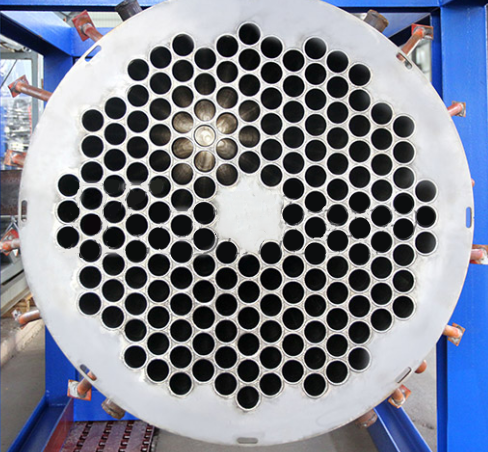

| Tube ice machine-Evaporator (1)The tube ice maker evaporator using high quality stainless steel 304 and other materials processing, meet international health standards; (2)we can do the OEM and follow you requirements for the trade mark . If you need ,we can produce evaporative condenser according to your design or conditions .The customized packing for tube ice machine condenser is also at your service. |

Tube Ice outlet Ice outlet: when the ice pipe falls, the ice cutting mechanism will operate and cut the ice pipe into the set size. |  |

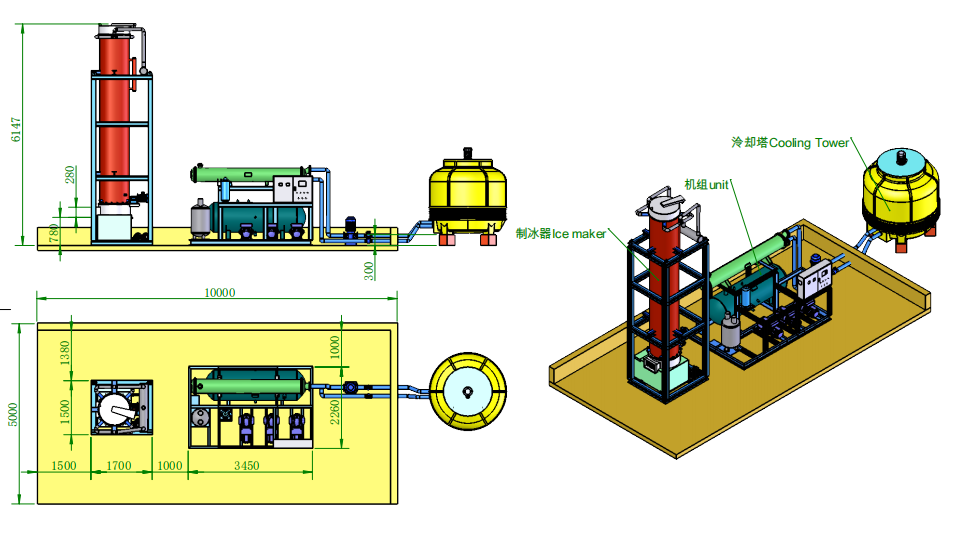

| Tube ice machine-Cooling tower All small type water-cooled tube ice machines are designed as integral type.

Water in the cooling tower is delivered by pump into condenser. The temperature goes high after it exchanges heat with refrigerant. Then the high temperature water is delivered back to the top of cooling tower for cooling. The cooled water recycled to the sunk below and be used again.

In the process of heat dissipation, some water will be evaporated into the air. Hence, cooling tower needs constant water supply when ice machine is running. |

3D Drawing of the Tube ice machine

10 ton Tube ice Application:

(2)Cafes,Bars,hotels and other places which need ice.

(3)Thermal Energy Storage/Concrete Cooling

(5)Fish/Seafood icing

(6)Logistics preservation

(7)Ports Ice Factory