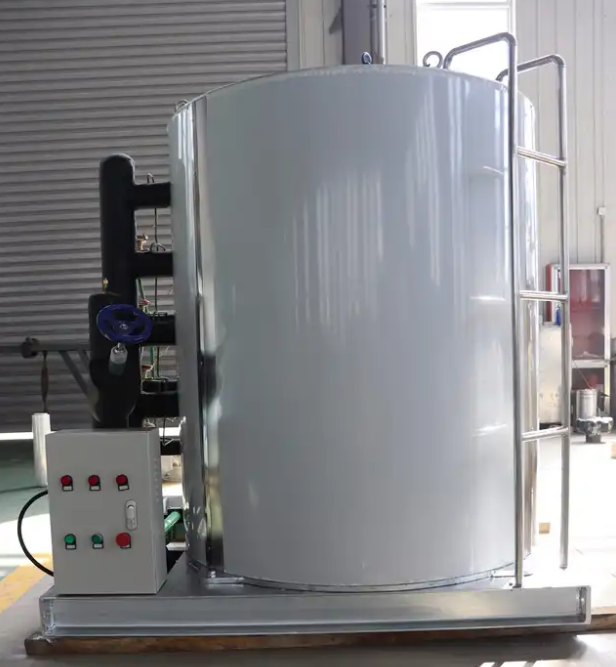

Flake Ice Evaporator drum with Ammonia Refrigeration System

- Robin

- Shandong China

- 20 working days

- 100 sets/Month

Ammonia system flake ice evaporator adopts fixed static vertical design, the material is high quality 304 stainless steel or high efficient heat conduction carbon steel plating nobelium, automatic protection welding equipment and heat treatment annealing furnace to ensure the high quality and performance of the evaporator.

Flake ice machine evaporator is widely used in the production of flake ice machine and ammonia system ice machine and other occasions. Users only need to connect the evaporator air tube to the refrigeration source to realize continuous ice making, easy to install and lower cost.

Flake Ice Evaporator Ammonia Refrigeration System

Evaporator introduction and structure:

The evaporator of flake ice machine is where the ice has been generated. It is a vertical placed drum shape container, equipped with the rotating blade which spin and scratch the ice of the inner wall of evaporator. When operating, the principle shaft and blade spins anti-clock wisely pushed by the reducer. Water is sprayed down from the sprinkler, then ice forms on the inner wall. Ice blade then scratches the ice off and ice drops down to the ice storage bin.

1. Strict qualitiy control, system

2. Radio graphic testing (X-RAY) for welds

3. Weldless forming for ice blade

4. heat treatment (annealing) for stress relief

5. Chromium coating for improved wear resistance (Carbon steel only)

6. Scientifically designed refrigerant chamber

7. Smooth ice scraping

8. No risk of deformation or refrigerant leakage

9. High stability, high cooling efficiency and long life (8-10year)

Products Features

1. Be made of low-temperature pressure vessel special materials and passed precision processing;

2. More sufficient evaporation area and better performance with dry style evaporation way;

3. Whole processing is made by vertical lathe to ensure the precision up to 2 ounces;

4. Be designed and produced with standard low-temperature pressure vessel manufacturing process, including surface treatment, heat treatment, gas-tight test, tensile&compression strength test, etc.

5. Using imported refrigeration accessories;

6. All water supply line are made of stainless steel, high sanitary condition;

7. Fast ice forming & falling speed, ice begins within 1 to 2 minutes.

8. Ice blade: made of SUS304 material seamless steel tube and formed through only one time process. It's durable.

9. Spindle and other accessories: made of SUS304 material through precision machining, and conform to food hygiene standards.

10. Thermal insulation: foaming machine filling with imported polyurethane foam insulation. Better effect.

Tips: (1)Evaporator size and installation direction can be customized according to customers' requirements;

(2)The material of evaporator wall and up and down pedestal is available (304&316).

Technical Parameter:

Model | Capacity (kg/24h) | Refrigerating capacity (kw) | Power supply | Total power (kw) | refrigerants | Dimension (mm) | Weight (kg) |

RBFE-0.5T | 500 | 3.7 | 3P/380V/50HZ | 0.32 | R404A/R22 | 900*580*780 | 115 |

RBFE-1T | 1,000 | 6.5 | 3P/380V/50HZ | 0.32 | R404A/R22 | 900*580*880 | 136 |

RBFE-1.2T | 1,200 | 7.8 | 3P/380V/50HZ | 0.32 | R404A/R22 | 900*580*980 | 148 |

RBFE-1.5T | 1,500 | 9.8 | 3P/380V/50HZ | 0.32 | R404A/R22 | 900*580*980 | 156 |

RBFE-2T | 2,000 | 13 | 3P/380V/50HZ | 0.39 | R404A/R22 | 910*680*1040 | 246 |

RBFE-2.5T | 2,500 | 16.2 | 3P/380V/50HZ | 0.39 | R404A/R22 | 910*680*1200 | 293 |

RBFE-3T | 3,000 | 19.5 | 3P/380V/50HZ | 0.39 | R404A/R22 | 910*680*1200 | 324 |

RBFE-4T | 4,000 | 26 | 3P/380V/50HZ | 0.57 | R404A/R22 | 1190*890*1250 | 368 |

RBFE-5T | 5,000 | 32.5 | 3P/380V/50HZ | 0.57 | R404A/R22 | 1190*890*1450 | 436 |

RBFE-8T | 8,000 | 49 | 3P/380V/50HZ | 0.95 | R22/R717 | 1720*1270*1560 | 638 |

RBFE-10T | 10,000 | 65 | 3P/380V/50HZ | 0.95 | R22/R717 | 1720*1270*1700 | 795 |

RBFE-15T | 15,000 | 95 | 3P/380V/50HZ | 1.2 | R22/R717 | 2160*1650*1865 | 1265 |

RBFE-20T | 20,000 | 130 | 3P/380V/50HZ | 1.2 | R22/R717 | 2160*1650*2050 | 1968 |

RBFE-25T | 25,000 | 160 | 3P/380V/50HZ | 1.2 | R22/R717 | 2160*1650*2265 | 2263 |

RBFE-30T | 30,000 | 195 | 3P/380V/50HZ | 1.89 | R22/R717 | 2860*2180*2350 | 2862 |

Detailed Of Flake Ice Machine evaporator with ammonia refrigeration system

| Famous motor and reducer brand We use the most famous motor and recuder brand Gongji from Taiwan, China, speed ratio is 1:800. Gongji brand reducer and motor are special design for the flake ice machine system, to keep the ice machine working in stable condition. |

Efficient Thermal Conductivity Evaporator Flake ice machine evaporator adopts fixed static vertical design, the material is high quality 304 stainless steel or high efficient heat conduction carbon steel plating nobelium, automatic protection welding equipment and heat treatment and annealing furnace to ensure that the evaporator high quality and performance. High-performance heat treatment annealing equipment, 850 ℃ high temperature annealing treatment can completely eliminate the workpiece welding residual internal stress. Ensure that the ice bucket good mechanical properties of the material, never deformed during use. |  |

| The ice scraper Robin company independent research and development production of spiral multi-bladed ice skates, the use of high-performance hard stainless steel molding production, scientific structure, clean and sanitary, reasonable spiral angle, precise cylindrical degree. Ensure low resistance to ice cutting, even ice cutting, no noise and vibration. |

Detailed picture of the ice evaproator

|  |