Automatic Vertical Ice Weighing and Packing Machine for Tube Ice

- Robin

- Shandong China

- 20 working days

- 100sets/Month

Full auto Waterproof Type Ice Ice Tube Bag Packing Machine

Multi-head combined weigher, improve metering speed and accuracy.

7inch touch screen, easy operation and multiple language for choice.

Imported PLC system, machine performance is stable and easy for parameters adjusting.

Withth a memory function for storage ten sets of parameters. Easy to change packing product.

Automatic Ice Packing Machine for Tube Ice

Robin automatic ice packing is mainly used for tube ice packing. It full-automatic weigh-form-fill-seal type, applying advanced operating system, easy to use and reprogramable.

Robin automatic ice packing is mainly used for tube ice packing. It full-automatic weigh-form-fill-seal type, applying advanced operating system, easy to use and reprogramable. Vertical form fill seal (VFFS) packaging machines are used in almost every industry today, for good reason: They are fast, economical packaging solutions that conserve valuable plant floor space.

Use famous brand electric and penumatic components, stable and long life circle. Use superior mechanical components, reduce the wear outless.

Easy to install film, auto correcting the excursion of the film. It makes your packing work easy and efficiency. It can pack 1-20 tons tube ice.

Auto Ice Packing Machine Features

1. Multi-head combined weigher, improve metering speed and accuracy.

2. 7inch touch screen, easy operation and multiple language for choice.

3. Imported PLC system, machine performance is stable and easy for parameters adjusting.

4. With a memory function for storage ten sets of parameters. Easy to change packing product.

5. Separate PID temperature controller, suitable for various packing materials.

6. Multi-union roll film pulling system make film running more smooth.

7. Adopt double servo film-dragging structure, enable stable bag forming for perfect bag shape.

8. Sophisticated sealing framework achieve the consistency of bag sealing and cutting.

Technical Parameters:

Metering capacity: | 1-20kg/bag |

Packing speed: | 8-15bag/min |

Bag type: | pillow bag |

Bag material: | LDPE film |

Max.outer diameter of reel: | Ф600 mm |

Bag size: | (50~460)×(80~350) mm |

(this machine own function of second-film pulling for set the bag length) | |

Details of Auto Ice Packing Machine:

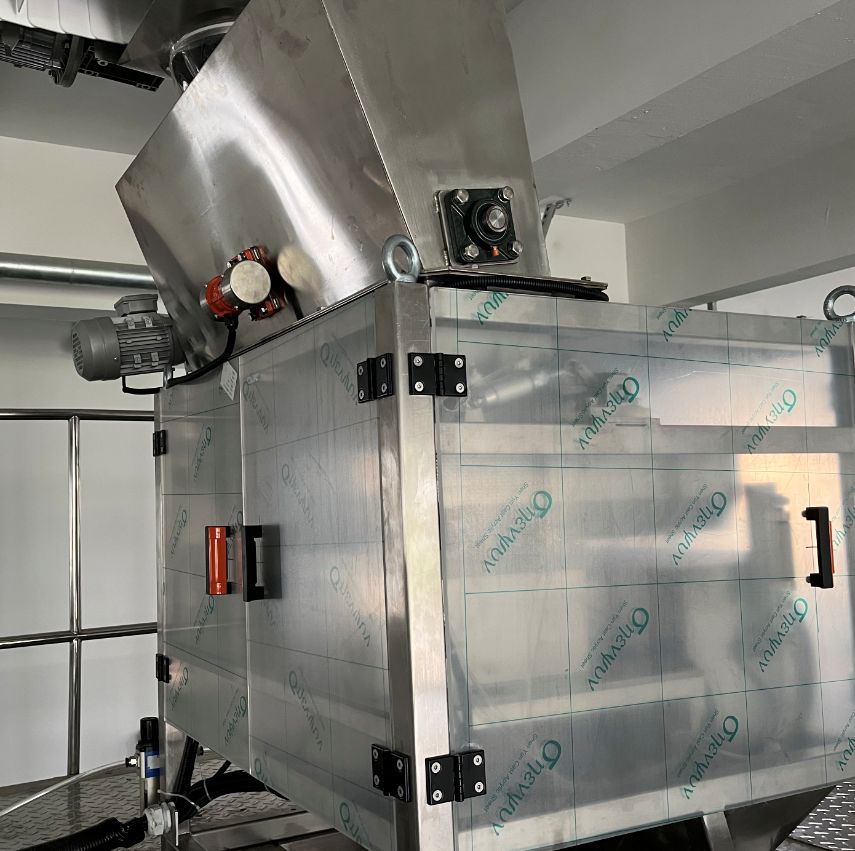

| 600L Storage hopper 1. We install the catchment tray on the large dip angle conveyor, the water happened during the convey process will be collect and back flow to the entrance 2. The whole machine is made of stainless steel 304 and food-grade plastic chain plates; 3. Equipped with stainless steel bearings; 4. Stainless steel 304 baffle is installed on the conveying section to prevent ice cubes from sliding down; 5. Stainless steel 304 baffles are added to both sides of the conveyor, with a height of 100 mm; 6. A water collecting tray is installed on the back of the conveyor to collect the water falling during the conveying process and return it to the inlet; 7. The conveying ascending section is equipped with a stainless steel guard plate, a rectangular window is dug on the guard plate, and plexiglass is installed; 8. 220V, single-phase, 50HZ, 1.1KW |

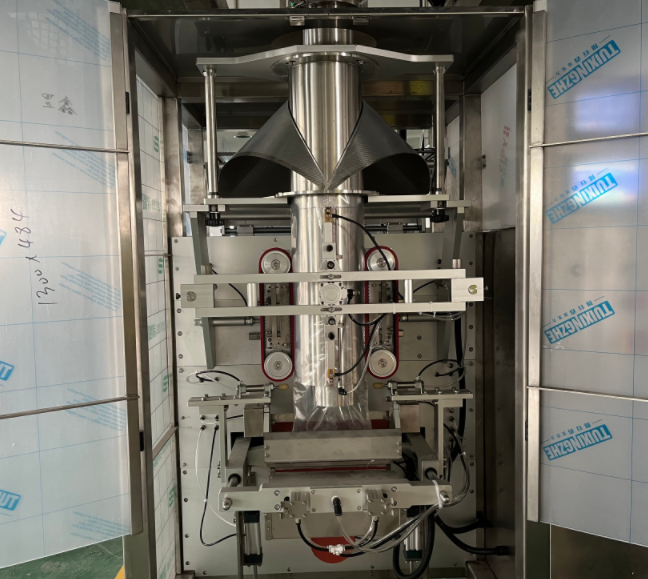

Automatic CJS5000 two heads weighing machine It owns 2 pairs of weighing hoppers , each pair consist of one fast supplier and one slow supplier, ensures the weighing capacity and speed. People pre-set and adjust the target weight and speed on the touch screen then the machine can weigh automatically. Each pairs of weighing head can weigh Max 5kg, double heads work together can weighing Max 10kg,Parts contact with ice are made by S.S304 |

|

| VFS730-B automatic vertical packing machine (PE film sealing system) 1.All of the components adopts international famous brand, PLC is SIEMENSE, servo motor is PANASONIC, touch screen is SIEMENSE, cylinder and air valve is Airtac. Electrical components are Schneider. 2.As the sealing system of the packing machine use laminated film and PE film is different, PE is not easy for sealing, sometimes not seal well, sometimes seal too much, we adopts the import Germany temperature controller ROPEX for controlling the heater strip for flash heating the PE film ) |

SIEMENS touch screen& temperature PANASONIC servo motor&driver Adjustment button & powder switch button make machine performance is stable and easy for parameters adjusting |

|

| Platform with guardrail and ladder The platform will be made by and stainless steel 304 ,anti slipy with ladder and guard rail, weight is about 100kg |

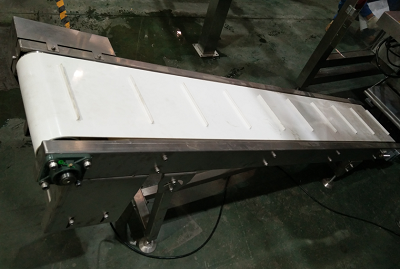

Take off conveyor The take off conveyor will be made by stainless steel 304 and the belt is food grade plastic rubber, length is 1.95m |  |

Installation:

1.We provide videos and instruction manual to show the process of installation.

2.We provide training for installation for free in our factory.

3.We can send technician to buyer's factory to install the machine and provide training service.