Hot Sale 10 20 30 35ton Tube Machine

- Robin

- Shandong China

- 20 working days

- 100 sets/Month

Large capacity ice tube machine features a modular design which makes it easy to install, ship and operate. The whole unit consists of 3 parts:

• Evaporator module: the evaporator and its accessories are installed on a steel frame which forms the evaporator module. When transporting, place the evaporator horizontally and stand it upright when installing.

• Compressor module: compressor, condenser, reservoir, liquid receiver, oil seperator, and electric control box are installed on a steel frame to form the whole set.

• Cooling tower module: cooling tower, water pump and water pipes.

Standard power supply for large capacity tube ice making machine is 380V/3P/50Hz and it can be customerized.

Hot Sale 10 20 30 35ton Tube Machine

Product advantages

Efficient ice making: The tube ice produced by the tube ice machine has a large specific surface area and can achieve rapid cooling effect in a short period of time. It is suitable for places that require rapid cooling, such as seafood markets and food transportation.

Energy saving and environmental protection: Compared with traditional ice making equipment, tube ice machines consume less energy during the ice making process, and the storage and transportation of ice are more efficient, reducing energy consumption and operating costs.

Excellent ice quality: The ice cubes produced by the tube ice machine have uniform texture, high transparency, and high hardness, which prolongs the melting time of ice and is suitable for situations that require long-term cooling, such as seafood preservation and food transportation.

High degree of automation: Modern ice pipe machines are usually equipped with automatic control systems, which can achieve fully automated operation, reduce manual intervention, and improve production efficiency and stability.

Compact structure: The tube ice maker has a compact structure, occupies a small area, is suitable for various spatial environments, and can provide efficient ice making capacity in limited space.

Wide applicability: The tube ice machine is suitable for multiple fields such as food processing, seafood storage and transportation, and pharmaceutical transportation, which can effectively extend the shelf life of food and drugs, ensuring their quality and safety.

Technical parameters of All the Robin Tube ice machine

Model | Daily output (T/ 24 h) | Compressor Power | Fan Power for Cooling Tower | Cooling Pump Power | Unit Size (L*W*H mm) (Integrated Type) | Unit N.W. (kg) | |

RBT-1T | 1 | 4.1 kw | 0.25 kw | 1.1 kw | 1100*900*1780 | 900 | |

RBT-2T | 2 | 7.44 kw | 0.25 kw | 1.5 kw | 1250*1000*1950 | 1200 | |

RBT-3T | 3 | 10 kw | 0.55 kw | 1.5 kw | 1300*1100*2200 | 1500 | |

RBT-5T | 5 | 19.9 kw` | 0.55 kw | 2.2 kw | 1600*1400*2250 | 1800 | |

Model |

Daily output |

Compressor |

Fan Power for Cooling Tower |

Cooling Pump Power | Unit size (L*W*H mm) |

Unit N.W. (kg) | |

Main Host | Brine Tank | ||||||

RBT-10T | 10 | 27.9 kw | 1.5 kw | 4 kw | 1900*1600*1850 | 1200*1200*3390 | 3500 |

RBT-12T | 10 | 39.8 kw | 1.5 kw | 4 kw | 2400*1700*2000 | 1200*1200*3390 | 3700 |

RBT-15T | 15 | 46.4 kw | 1.5 kw | 5 kw | 2700*2000*2200 | 1500*1200*4250 | 4250 |

RBT-20T | 20 | 55.7 kw | 2.2 kw | 7.5 kw | 2800*2200*2500 | 1500*1200*4700 | 6500 |

RBT-30T | 30 | 83.6 kw | 2.2 kw | 7.5 kw | 3100*2200*2500 | 1800*1500*5700 | 7200 |

RBT -40T | 40 | 111.4 kw | 2.2 kw | 11 kw | 3900*2250*2500 | 2000*1500*6800 | 8300 |

RBT-50T | 50 | 139.3 kw | 3.75 kw | 15 kw | 4500*2250*2500 | 2200*1800*7200 | 9500 |

1. Compressor brand: Bitzer /Franscold ; Refrigerant: R 22/ R 404 A; Cooling Method: water cooling / air cooling.2.Power supply: | |||||||

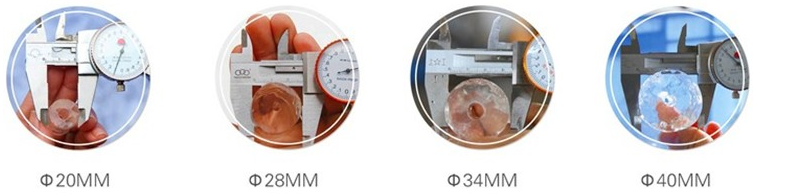

Ice tube Size as option

Tube ice outer diameter is 16mm,22mm, 28mm, 34mm, 40mm; The inner diameter can be adjusted according to the ice making time. Usually it's between 5~10mm.

| External Diameter | Standard Length | Freezing time |

| 16mm | 25mm | 14 minutes |

| 20mm | 30mm | 16 minutes |

| 28mm | 35mm | 18 minutes |

| 34mm | 45mm | 20 minutes |

| 40mm | 55mm | 25 minutes |

Details of the tube Ice Machine

| Compressor In split machine, the compressor is placed under the frame. The compressor is the only engine in the refrigeration system, just like the human heart, so the quality of the compressor will affect the refrigeration effect. The Bitzer brand is a high-quality brand widely used around the world. An internationally renowned brand with a long service life, good stability, high refrigeration efficiency, and low maintenance costs in the later stage. |

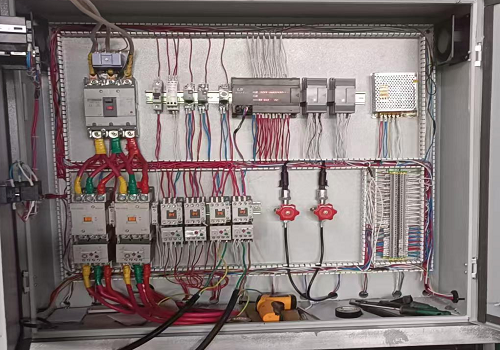

PLC control system Ice discharge automatically hygienic and labor-saving Like the brain of the human being to control the machine do the proper work in the right time. The ice thickness can be adjusted.Record the history of machine work. Set the operating parameters of the machine.Easy to find fault causes in the event of a machine failure |

|

| Evaporator Tubes This is the evaporator tube inside the tube ice machine evaporator, and tube ice is formed in the evaporator tube. The evaporator tube is made of alloy material, with good quality, and will not rust, deform or produce harmful substances in low temperature and high humidity environments; Ice tubes that meet food safety standards and come into direct contact with them are edible; Long service life. |

Applications of Tube Ice

Tube ice, especially the hollow column ice produced by tube ice machine, has a wide range of applications in many fields because of its regular shape, high hardness and slow melting.

Food processing and preservation: In the food processing industry, the fresh ice provided by tube ice machine can be used for preservation of seafood and meat, which can extend the shelf life of food by lowering the temperature. In addition, beverage production lines require large quantities of ice for cooling to ensure the taste and quality of beverages. The hollow design of tube ice increases the specific surface area of the ice, which helps to reduce the temperature of the food quickly. At the same time, due to its slow melting speed, it can maintain a low-temperature environment for a long time, which makes it ideal for use in the long-time preservation and transportation of food.

Cold chain logistics: in cold chain logistics, tube ice machine can provide a stable ice source for food products that need to be kept at low temperatures during transportation to ensure the freshness and quality of food products during transportation. Tube ice has a slow melting speed and high hardness, which is very suitable for cold storage and freshness preservation in long-distance transportation.

Catering industry: the catering industry has the same huge demand for ice, tube ice machine can quickly provide high-quality ice, used to make drinks, refrigerated ingredients, etc., to enhance the customer's dining experience. In addition, tube ice can also be used to make ice sculptures, chilled desserts, etc., to increase the ornamental and fun of the dining place.

Supermarkets and superstores: Supermarkets and superstores usually need to use a large amount of ice in the area of fish, meat and fresh products to keep these products at a low temperature and prevent deterioration. The high throughput of tube ice machines meets this need and ensures that fresh products in supermarkets and hypermarkets are always kept in the best condition.

After-sales service

1. During the production process of the machine, we will confirm the production progress of the machine with you in real time, and provide debugging quality inspection videos and reports at any time.

2. Arrange one-to-one technical engineers to serve you and provide professional service advice.

3. 18 months long-term warranty (other companies usually 12 months)

4. During the warranty period, if there is any problem with the machine, we will unconditionally provide raw material parts for free. If necessary, we can arrange technicians to visit your home for maintenance and repair.

5. After the warranty period, if any problem occurs on the machine, we will also arrange engineers to provide professional service + original spare parts (spare parts cost at your own expense)