New Advanced High Quality 25 Ton Tube Ice Machine

- Robin

- Shandong, China

- 30 to 45 working days

- 100 sets/Month

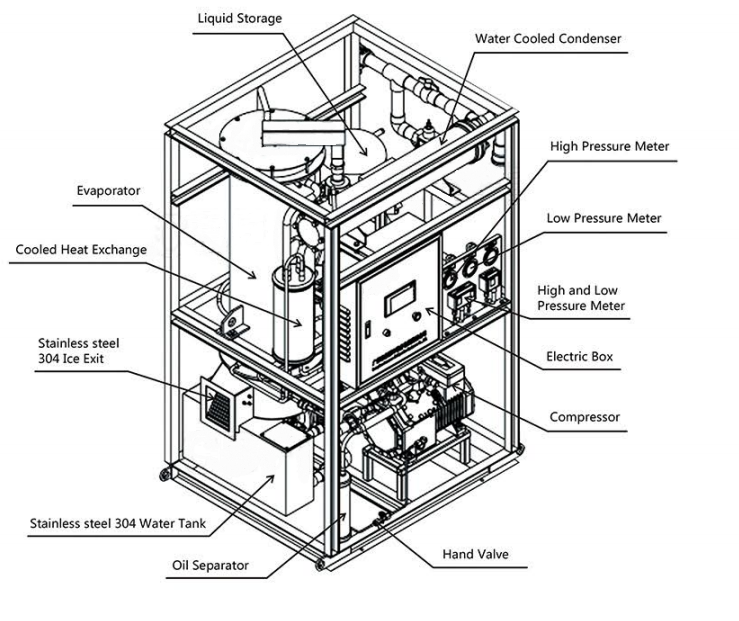

25 Ton ice tube machine features a modular design which makes it easy to install, ship and operate. The whole unit consists of 3 parts:

• Evaporator module: the evaporator and its accessories are installed on a steel frame which forms the evaporator module. When transporting, place the evaporator horizontally and stand it upright when installing.

• Compressor module: compressor, condenser, reservoir, liquid receiver, oil separator, and electric control box are installed on a steel frame to form the whole set.

• Cooling tower module: cooling tower, water pump and water pipes.

Standard power supply for large capacity tube ice making machine is 380 V/3 P/50 Hz and it can be customerised.

New Advanced High Quality 25 Ton Tube Ice Machine

25 Ton ice tube machine features a modular design which makes it easy to install, ship and operate. The whole unit consists of 3 parts:

• Evaporator module: the evaporator and its accessories are installed on a steel frame which forms the evaporator module. When transporting, place the evaporator horizontally and stand it upright when installing.

• Compressor module: compressor, condenser, reservoir, liquid receiver, oil separator, and electric control box are installed on a steel frame to form the whole set.

• Cooling tower module: cooling tower, water pump and water pipes.

Standard power supply for large capacity tube ice making machine is 380 V/3 P/50 Hz and it can be customerised.

Quick Details

Condition: New

Ice Shape: tube ice

Voltage: 380v/50hz/3p

Power: 85.3kw

Dimension(L*W*H): 1450*1450*4800mm

Weight: 8500kg

Certification: CE

Warranty: 1 Year, 15months

Ice storage capacity: Customize to your needs

Warranty of core components: 1 Year

Core Components: PLC

Name: 25ton tube ice machine

Cooling way: Evaporative Cooling

Refrigerant: R404A/R22

Type: Automatic Ice Making Machine

Ice Size: Customized Size

Capacity: 25ton

Technical parameters of All the Robin Tube ice machine

Model | Daily output (T/ 24 h) | Compressor Power | Fan Power for Cooling Tower | Cooling Pump Power | Unit Size (L*W*H mm) (Integrated Type) | Unit N.W. (kg) | |

RBT-1T | 1 | 4.1 kw | 0.25 kw | 1.1 kw | 1100*900*1780 | 900 | |

RBT-2T | 2 | 7.44 kw | 0.25 kw | 1.5 kw | 1250*1000*1950 | 1200 | |

RBT-3T | 3 | 10 kw | 0.55 kw | 1.5 kw | 1300*1100*2200 | 1500 | |

RBT-5T | 5 | 19.9 kw` | 0.55 kw | 2.2 kw | 1600*1400*2250 | 1800 | |

Model |

Daily output |

Compressor | Fan Power for Cooling Tower |

Cooling Pump Power | Unit size (L*W*H mm) |

Unit N.W. (kg) | |

Main Host | Brine Tank | ||||||

RBT-10T | 10 | 27.9 kw | 1.5 kw | 4 kw | 1900*1600*1850 | 1200*1200*3390 | 3500 |

RBT-12T | 10 | 39.8 kw | 1.5 kw | 4 kw | 2400*1700*2000 | 1200*1200*3390 | 3700 |

RBT-15T | 15 | 46.4 kw | 1.5 kw | 5 kw | 2700*2000*2200 | 1500*1200*4250 | 4250 |

RBT-20T | 20 | 55.7 kw | 2.2 kw | 7.5 kw | 2800*2200*2500 | 1500*1200*4700 | 6500 |

RBT-30T | 30 | 83.6 kw | 2.2 kw | 7.5 kw | 3100*2200*2500 | 1800*1500*5700 | 7200 |

RBT -40T | 40 | 111.4 kw | 2.2 kw | 11 kw | 3900*2250*2500 | 2000*1500*6800 | 8300 |

RBT-50T | 50 | 139.3 kw | 3.75 kw | 15 kw | 4500*2250*2500 | 2200*1800*7200 | 9500 |

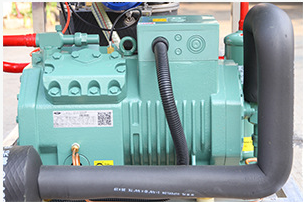

1. Compressor brand: Bitzer /Franscold ; Refrigerant: R 22/ R 404 A; Cooling Method: water cooling / air cooling.2.Power supply: | |||||||

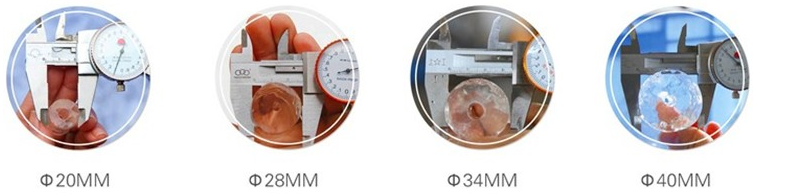

Ice tube Size as option

Tube ice outer diameter is 16mm,22mm, 28mm, 34mm, 40mm; The inner diameter can be adjusted according to the ice making time. Usually it's between 5~10mm.

| External Diameter | Standard Length | Freezing time |

| 16mm | 25mm | 14 minutes |

| 20mm | 30mm | 16 minutes |

| 28mm | 35mm | 18 minutes |

| 34mm | 45mm | 20 minutes |

| 40mm | 55mm | 25 minutes |

Ice machine with the Autumatick ice packing machine

Detailed Drawings of the tube Ice Machine

| Bitzer compressor: high efficiency, low loss, low noise, long service life. |

| Touch screen: simple operation: the electric control box adopts PLC microcomputer program control, automatic ice forming, automatic ice dropping, automatic ice out and fault intelligent display. |  |

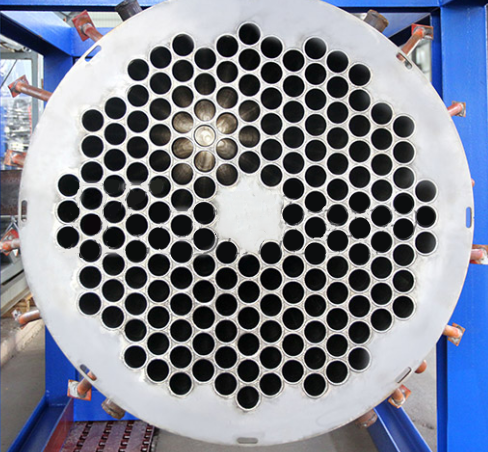

| Evaporation barrel: material using SUS304.PE, aluminum alloy and other materials processing, the use of large rounded corner over set.So that there is no dead Angle of cleaning inside the equipment. |

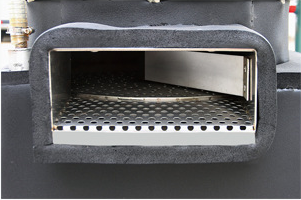

| Ice outlet: when the ice pipe falls, the ice cutting mechanism will operate and cut the ice pipe into the set size. |  |

| Evaporator: SS 304 inside, PU insulation and also the SS 304 cladding outside to keep the top quality and long life spans. |