10 Tons Industrial Ice Tube Maker Machine With PLC Controller

- Robin

- Shandong China

- 20 working days

- 100 sets/Month

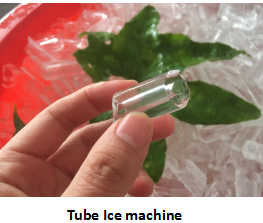

Robin tube ice machine is a type ice machine, which produces cylinder shape ice with a hole in the middle; it adopts flooded evaporator model, which improves ice making efficiency and capacity. Meanwhile, compact structure design can save installation space. Ice thickness and hollow part size can be adjusted according to customer requirements. Under PLC program control system to work automatically, the machine has high capacity, low-power consumption, and minimal maintenance.

10 Tons Industrial Ice Tube Maker Machine With PLC Controller

Robin 10-ton tube ice machine is meticulously crafted from selected high-quality SS304 stainless steel, a material that is not only corrosion-resistant and strong, but also ensures the stability and durability of the machine in long-term operation, thus guaranteeing the superior quality of the product. The machine is personally designed and made by a team of experienced and professional engineers, and each step of the process contains craftsmanship and exquisite skills, providing users with a solid quality guarantee.

In the selection of accessories, Robin 10 ton tube ice machine strictly follows the industry standards and uses all the high quality components recognized in the industry, which have been strictly screened and tested to ensure the excellent performance and smooth operation of the whole machine. This configuration makes the ice produced crystal clear, not only attractive appearance, but also in the application of the application shows a very low rate of ice breakage, effectively improve the utilization rate of ice, for users to save costs.

Robin has always taken “quality first” as the core concept of the enterprise, from design, material selection, manufacturing to finished product inspection, every link is strictly controlled, and strive to achieve the highest standards in every detail. It is this persistent pursuit of quality that makes Robin 10-ton tube ice machine stand out in the market, with its unparalleled quality to win the widespread favor and trust of customers. Whether it is food processing, cold chain logistics or other areas that require efficient ice production, Robin 10-ton tube ice machine has become one of the first choices for many customers with its outstanding performance and reliable quality.

Technical parameters of 10 ton Tube ice machine

Capacity | 10 Ton/24hours |

Refrigerant | R22/R404A/R507/R449 |

Compressor Brand | Bitzer/Refcomp |

Cooling Way | Water Cooling |

Cooling capacity (kw) | 78.2 KW |

Compressor input power (kw) | 30.4 KW |

Reducer power | 1.5 KW |

Water pump of cooling power | 4 KW |

Machinery Unit Size(L*W*H) | 2200mm*1600mm*3100mm |

Machinery Unit Weight | About 3000kg |

Input Water Temp | 25 ℃ |

Evaporating Temp | -12 ℃ |

Condensing Temp | 40℃ |

Supply power | 380V/50Hz(60Hz)/3P; 220V(230V)/50Hz/1P; 220V/60Hz/3P(1P); 415V/50Hz/3P; 440V/60Hz/3P. |

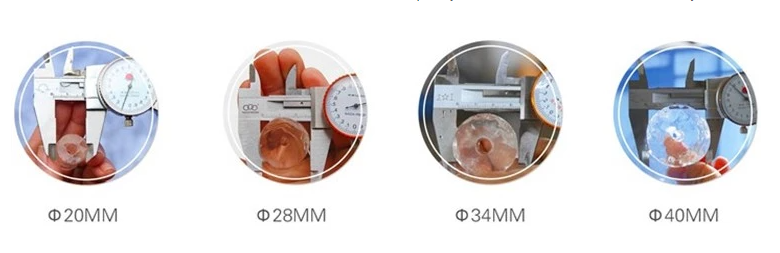

Multi Ice Tube Size Option

Tube ice diameter is 20mm, 28mm, 34mm, 40mm; Tube ice length:30mm, 35mm, 40mm, 45mm, 50mm.

Tube Ice Machine details

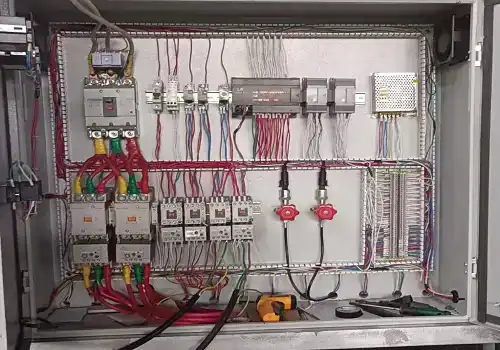

| Compressor The compressor is the only engine of the refrigeration system, it's just as the heart for a human being, so the quality of compressor enfluence the refrigeration effect. Bitzer brand is good quality one, and widely used all over the world. Internationally renowned brands, long service life, good stability, high refrigeration efficiency, and low maintenance cost in the later stage. It adopts double parallel connection, good maintenance, small starting power, and smoother operation of the equipment. |

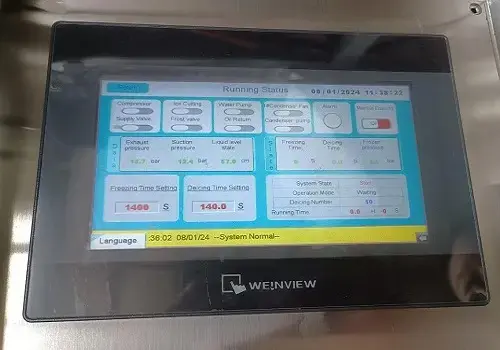

Touch Screen The touch screen, as its important human-machine interface, provides an intuitive and easy operation experience. Equipped with PLC intelligent control system, users can realize various functions such as automatic startup and shutdown of the machine, automatic ice lowering after ensuring freezing time, automatic water replenishment and so on by one-key operation through the color touch screen. Improve efficiency and monitor the operation status in real time. |

|

| PLC control system Ice discharge automatically hygienic and labor-saving Like the brain of the human being to control the machine do the proper work in the right time. The ice thickness can be adjusted. Record the history of machine work Set the operating parameters of the machine Easy to find fault causes in the event of a machine failure |

Tube ice application

Tube ice, especially the hollow column ice produced by tube ice machine, has a wide range of applications in many fields because of its regular shape, high hardness and slow melting.

Food processing and preservation: In the food processing industry, the fresh ice provided by tube ice machine can be used for preservation of seafood and meat, which can extend the shelf life of food by lowering the temperature. In addition, beverage production lines require large quantities of ice for cooling to ensure the taste and quality of beverages. The hollow design of tube ice increases the specific surface area of the ice, which helps to reduce the temperature of the food quickly. At the same time, due to its slow melting speed, it can maintain a low-temperature environment for a long time, which makes it ideal for use in the long-time preservation and transportation of food.

Catering industry: the catering industry has the same huge demand for ice, tube ice machine can quickly provide high-quality ice, used to make drinks, refrigerated ingredients, etc., to enhance the customer's dining experience. In addition, tube ice can also be used to make ice sculptures, chilled desserts, etc., to increase the ornamental and fun of the dining place.

Supermarkets and superstores: Supermarkets and superstores usually need to use a large amount of ice in the area of fish, meat and fresh products to keep these products at a low temperature and prevent deterioration. The high throughput of tube ice machines meets this need and ensures that fresh products in supermarkets and hypermarkets are always kept in the best condition.

Cold chain logistics: in cold chain logistics, tube ice machine can provide a stable ice source for food products that need to be kept at low temperatures during transportation to ensure the freshness and quality of food products during transportation. Tube ice has a slow melting speed and high hardness, which is very suitable for cold storage and freshness preservation in long-distance transportation.

Packaging and Shipping

Robin's Tube Ice Machine's entire capacity is typically 1 ton to 30 tons, and the most common packaging is wooden crates packed by sea.

We accept EXW, FOB, CIF and other transportation terms, and DDP and DDU are also available in some areas.

FAQ

1.What are the payment terms?

Our preferred method of payment is via wire transfer. The terms are as follows: an initial 40% deposit is required to secure your order, and the remaining 60% balance is to be settled prior to the delivery of your machine.

2.Do I need to install the ice machine myself?

For smaller models, the ice machines are shipped as a complete unit, requiring only the connection of utilities to operate. For larger units that are shipped in parts for easier transportation, we provide a comprehensive installation manual. The manual is straightforward, making the assembly process manageable. Should you encounter any difficulties, our technical support team is always available to assist you.

3.How long is the warranty on the ice machine?

We offer a comprehensive 18-month warranty from the date of purchase or delivery. During this period, we will supply any necessary spare parts free of charge if a failure occurs due to our manufacturing defect. Additionally, we provide lifetime technical support and advice to ensure your ice machine operates efficiently and reliably.

4. Are you add refrigerant in the ice machine?

The model which is for export will not added with refrigerant by default.If there are any special requirements,negotiations will be available

5. Do you test the ice machine in your factory?

Yes, Our ice machine be tested twice before shipping and we will send testing video to you.Factory inspection and operation test after installation at the buyer's destination.In addition, our company can provide a complete set of solutions for the actual needs of customers.Creating value and fulfilling customers is our principle.

6. Can I custom 220V 50HZ/ 380V 50HZ / 440V 60HZ three phase power ?

Yes, we can custom power, voltage can suitable for your country, please make the power requirement be clear in your order.

7. Whats the deliver time of your machine?

Standard power 220V 50HZ production 20-35 days;380V/440V custom power production time 30-35 days.

8. How Can You Guarantee The Quality?

1) We have our quality department to inspect the quality during the production process.

2) We will test the whole machine in our workshop and testing pictures or videos can be provided to you for checking.