Automatic Tube Ice Maker With Advanced Technology

- Robin

- Shandong, China

- 30-45 working days

- 50 sets / month

Robin RB series tube ice machine is a type ice machine, which produces cylinder shape ice with a hole in the middle; it adopts flooded evaporator model, which improves ice making efficiency and capacity. Meanwhile, compact structure design can save installation space. Ice thickness and hollow part size can be adjusted according to customer requirements. Under PLC program control system to work automatically, the machine has high capacity, low-power consumption and minimal maintenance.

Automatic Tube Ice Maker With Advanced Technology

Robin RB series tube ice machine is a type ice machine, which produces cylinder shape ice with a hole in the middle; it adopts flooded evaporator model, which improves ice making efficiency and capacity. Meanwhile, compact structure design can save installation space. Ice thickness and hollow part size can be adjusted according to customer requirements. Under PLC program control system to work automatically, the machine has high capacity, low-power consumption and minimal maintenance.

Technical parameters of All the Robin Tube ice machine

Model | Daily output (T/ 24 h) | Compressor Power | Fan Power for Cooling Tower | Cooling Pump Power | Unit Size (L*W*H mm) (Integrated Type) | Unit N.W. (kg) | |

RBT-1T | 1 | 4.1 kw | 0.25 kw | 1.1 kw | 1100*900*1780 | 900 | |

RBT-2T | 2 | 7.44 kw | 0.25 kw | 1.5 kw | 1250*1000*1950 | 1200 | |

RBT-3T | 3 | 10 kw | 0.55 kw | 1.5 kw | 1300*1100*2200 | 1500 | |

RBT-5T | 5 | 19.9 kw` | 0.55 kw | 2.2 kw | 1600*1400*2250 | 1800 | |

Model |

Daily output |

Compressor | Fan Power for Cooling Tower |

Cooling Pump Power | Unit size (L*W*H mm) |

Unit N.W. (kg) | |

Main Host | Brine Tank | ||||||

RBT-10T | 10 | 27.9 kw | 1.5 kw | 4 kw | 1900*1600*1850 | 1200*1200*3390 | 3500 |

RBT-12T | 10 | 39.8 kw | 1.5 kw | 4 kw | 2400*1700*2000 | 1200*1200*3390 | 3700 |

RBT-15T | 15 | 46.4 kw | 1.5 kw | 5 kw | 2700*2000*2200 | 1500*1200*4250 | 4250 |

RBT-20T | 20 | 55.7 kw | 2.2 kw | 7.5 kw | 2800*2200*2500 | 1500*1200*4700 | 6500 |

RBT-30T | 30 | 83.6 kw | 2.2 kw | 7.5 kw | 3100*2200*2500 | 1800*1500*5700 | 7200 |

RBT -40T | 40 | 111.4 kw | 2.2 kw | 11 kw | 3900*2250*2500 | 2000*1500*6800 | 8300 |

RBT-50T | 50 | 139.3 kw | 3.75 kw | 15 kw | 4500*2250*2500 | 2200*1800*7200 | 9500 |

1. Compressor brand: Bitzer /Franscold ; Refrigerant: R 22/ R 404 A; Cooling Method: water cooling / air cooling.2.Power supply: | |||||||

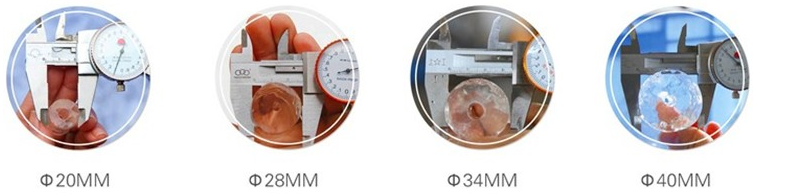

Ice tube Size as option

Tube ice outer diameter is 16mm,22mm, 28mm, 34mm, 40mm; The inner diameter can be adjusted according to the ice making time. Usually it's between 5~10mm.

| External Diameter | Standard Length | Freezing time |

| 16mm | 25mm | 14 minutes |

| 20mm | 30mm | 16 minutes |

| 28mm | 35mm | 18 minutes |

| 34mm | 45mm | 20 minutes |

| 40mm | 55mm | 25 minutes |

Tube Ice Machine Application:

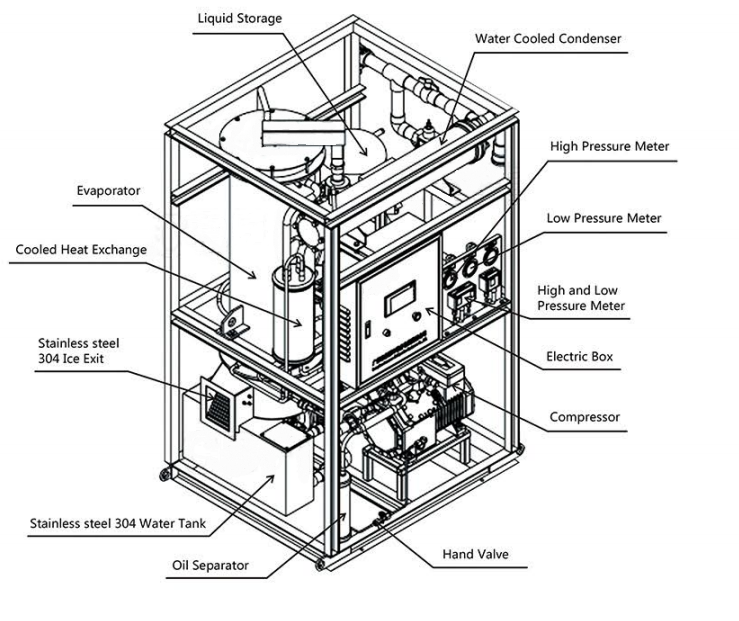

Detailed Drawings of the tube Ice Machine

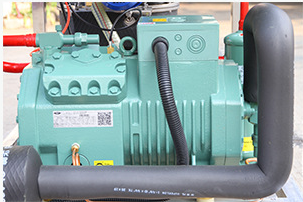

| Bitzer compressor: To facilitate installation and shipment, Linsky large capacity tube ice machine features modular design. The whole unit consists of 3 parts, compressor module, evaporator module and cooling tower module. Compressor module: Compressor, water condenser, reservoir, liquid receiver, oil separator, and electric control box are all installed on the steel frame. high efficiency, low loss,low noise, long service life. |

Tube ice machine-Electronic components (1)The tube ice machine adopts the integrated design, compact structure, easy installation and use; (2)PLC man-machine interface computer module, ice making and ice automatically switches off, save time and effort; (3)All equipment using CAD, 3D simulation assembly, arrangement of equipment parts and accessories, pipe to more reasonable,compact structure and not crowded, operation, maintenance more human; (4)According to different working condition of customized, non-standard tube ice machines can be made. |  |

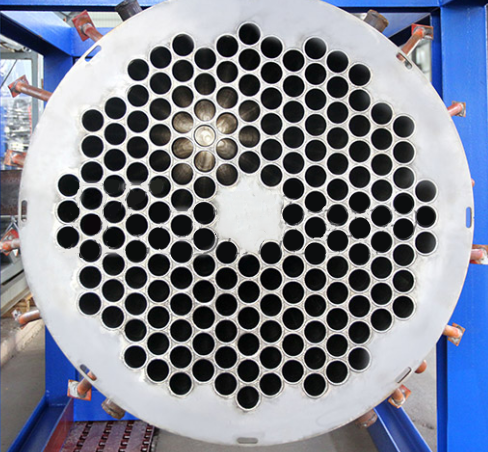

| Evaporation barrel: material using SUS304.PE, aluminum alloy and other materials processing, the use of large rounded corner over set.So that there is no dead Angle of cleaning inside the equipment. |

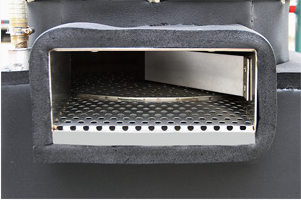

| Ice outlet: when the ice pipe falls, the ice cutting mechanism will operate and cut the ice pipe into the set size. |  |

| Evaporator: SS 304 inside, PU insulation and also the SS 304 cladding outside to keep the top quality and long life spans. |